Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

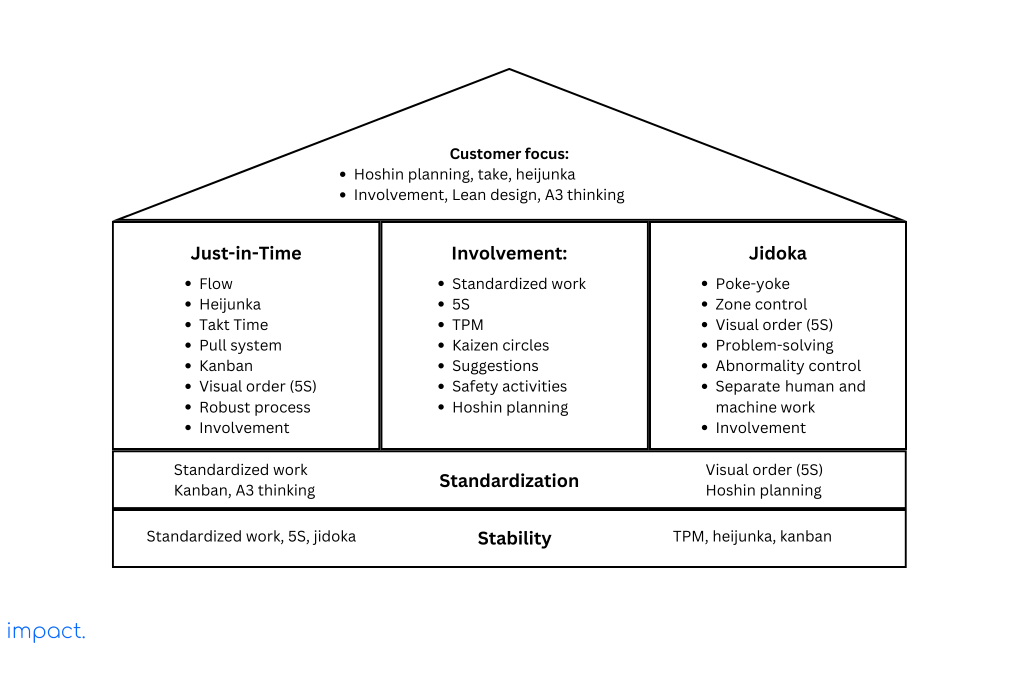

May 17, 2025This chapter will delve into another essential House of Lean Production pillar: standardization. The main focus will be on standardized work.

Standardized work comes into play once we have established stability in the production process. Achieving this stability is made possible through the implementation of 5S and TPM.

Standardized work (SW) is the cornerstone of continuous improvement, relying on consistent work processes. It reduces waste, improves work time and efficiency, and increases job satisfaction. In the following sections, we will dive into the definition, elements, charts, and benefits of standardized work.

Standardized work ensures safety, ease, and optimal performance. At Toyota, workers are responsible for designing their work, as there is no one-size-fits-all approach. Moreover, standardized work serves as a foundation for driving improvements.

Even the most efficient processes contain waste, which is why standard work is in a constant state of evolution. Regrettably, standardization has become another rigid command and control management tool in numerous organizations.

Frank and Lillian Gilbreth built upon Fred Taylor’s concept of the “single best way” and devised a method that continues to be employed by industrial engineers to this day. Industrial engineering practice relies on unspoken assumptions, namely:

Read more: Lean Manufacturing: Definition & 3 Advantages to Utilize

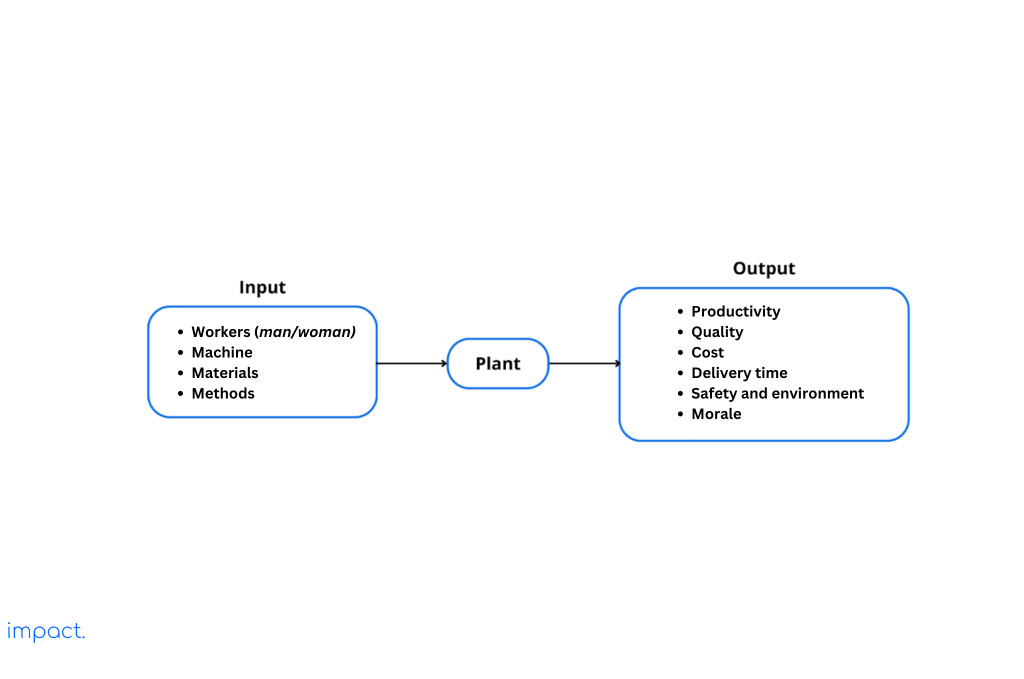

The company aims to meet the expectations of both the company and customers by providing the required output in terms of:

Standardized work is a helpful tool for creating, confirming, and improving how we do things in a company. The 4 Ms – People, Machines, Materials, and Methods – are the essential tools used in work.

People refer to the team members, Machines are the equipment like conveyors, Materials include the raw materials and parts from suppliers, and Methods represent the work process. Methods are the way workers, machines, and materials come together.

A process consists of clear goals and a sequence of steps or actions. It involves informing team members of their tasks, timing, and order. Let’s look into how this system operates within the production process:

Most companies think that the way to become more efficient is by using machines more. However, we need to understand that to make the most of devices, we have to:

This approach produces additional waste, so Toyota wants to maximize human skills. Machines provide more benefits than human flexibility. For example, an operator can:

As a result, companies favor small and straightforward machines over larger ones. They are typically more affordable, powerful, and adaptable to changing demands. For instance, if there is an increase in demand, a company can add another small machine.

Companies should focus on creating processes that prioritize the well-being of their employees and ensure smooth and safe operations. The efficiency of these processes can be measured using a metric called labor density, which is defined as follows:

| Labor density = Work ÷ Movement |

Implementing standardized work brings numerous benefits to companies. Here are some of the key advantages:

To meet standards, companies must avoid constant line stoppages and slowdowns. Here are familiar sources of instability:

To ensure machine stability, implementing 5S and TPM is crucial. Jidoka helps improve the quality, while the Just-in-Time (JIT) technique helps address spare parts shortages. Additionally, implementing 5S, TPM, and standardized work can enhance safety. Incorporating lean activities is essential for promoting stability, quality, and security.

Standardized work consists of three elements:

These elements provide a baseline for assessing a particular process during production. The following further explains each component:

Takt time is a formula that informs companies about the frequency of demand or how often we need to produce a product. Here is how to calculate takt time:

| Takt time = Daily operating time ÷ Quantity required per day |

Takt time and cycle time are distinct. Takt time is the interval between initiating one unit and commencing the next. In contrast, cycle time represents the duration needed to complete a process.

A company aims to align takt and cycle times as closely as possible. This alignment enables the integration of processes into cells, which facilitates the achievement of individual production objectives. Additionally, takt time provides a quick overview of the company’s production conditions.

The work order defines the precise sequence of tasks within a process. For instance, team members might need to follow these steps:

Clearly define each job action’s optimal method and sequence to ensure efficient job performance. Toyota uses illustrations to show:

Toyota prioritizes its people and utilizes the visual nature of standardized work as a powerful tool for enhancing safety and ergonomics.

The operator needs a minimum number of unfinished workpieces to continue working without standing at the machine. This element is called “in-process.” It’s essential because work can’t proceed without a certain quantity of goods available. Companies should increase their stock in process in the following situations:

Setting a standard for in-process stock clarifies issues and establishes the Work-in-Progress (WIP) per process.

To create standard work, team members should collaborate with engineers and other experts when needed. You can use these three different charts for this purpose:

Each chart serves as a tool to analyze and define a process while identifying areas for improvement.

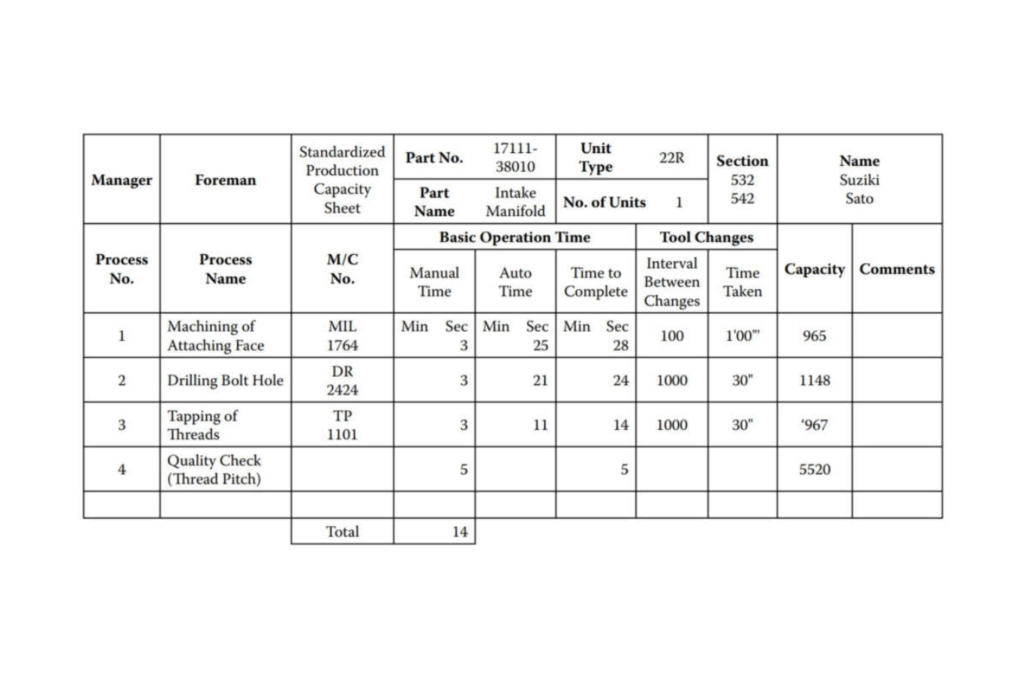

This chart determines the capacity of the machine in a process. It aids in documenting device and manual time, enabling companies to identify bottlenecks quickly. To calculate the production capacity of a specific device, use the following formula:

| Capacity = Operational time per shift ÷ (Processing time + Setup time/interval) |

Setup time is the time it takes to switch from one machine setting to another. A punch press involves changing dies, adjusting machine settings, and loading new steel coils. Conversely, interval refers to the frequency of tuning based on the number of parts.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; Production Capacity Chart

The graph above shows the production capacity calculation for the drilling machine used in process 2. Here are the relevant details:

To calculate the capacity, divide 27,600 seconds by (24 + 30/1000). The result is 1,148.5 parts. Therefore, the drill machine has a power of 1,148 parts per shift.

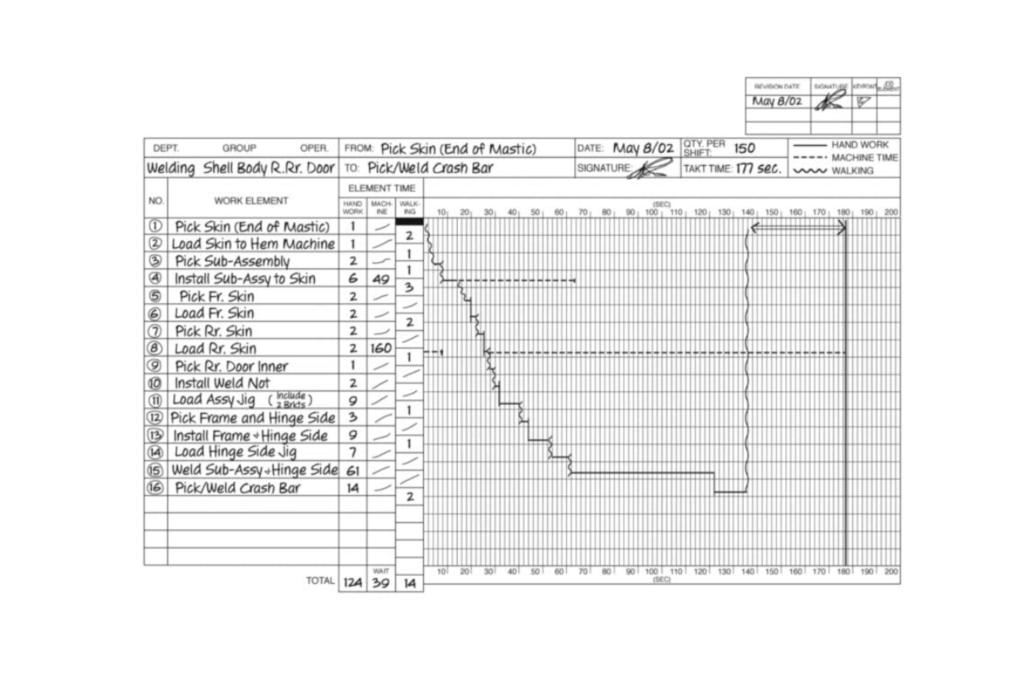

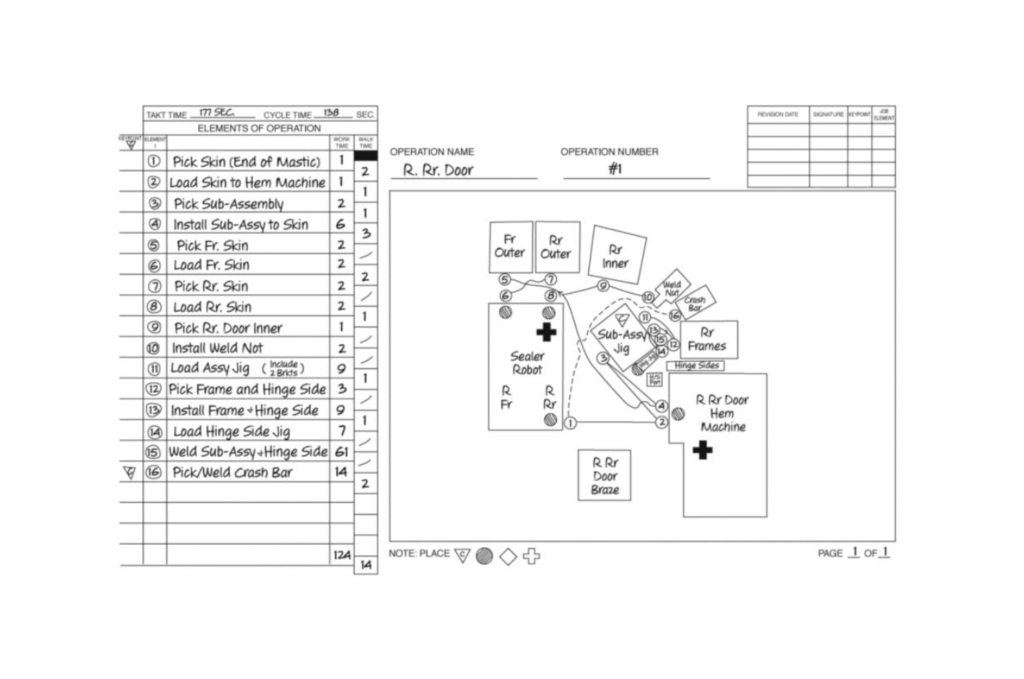

This chart presents the order of work tasks and the time needed for each job. It also shows the time spent by the operator and the machine and any interactions between the operator and the device or among different operators.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; Standardized work combination table.

These charts simplify building kaizen by breaking down operator movements and connecting them to machine times.

These charts serve to rationalize layouts and train workers by including the following components:

Source: Dennis, P. (2017); Lean Manufacturing Simplified; Standard work analysis chart.

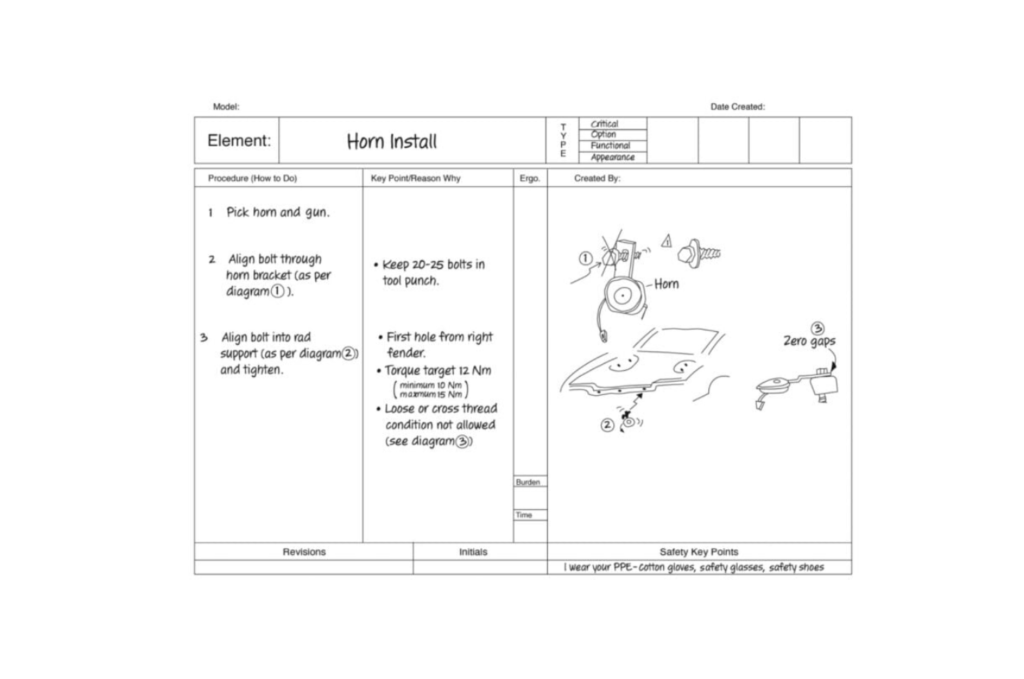

Job elements comprise the important actions or action groups needed to progress a process. The Job Element Sheet (JES) is a concise, one-page document that provides specific information, including:

Team members have accumulated valuable work records and learning points over the years, making JES an invaluable tool for recording them. JES serves as an essential intermediate step toward achieving standardized work. The image below displays the actual form of JES.

Source: Dennis, P. (2017); Lean Manufacturing Simplified; Job element sheet.

Break down the process into its elements to measure time and count each element’s start and stop times. Here are the required steps:

At Toyota, time measurement can give valuable insights into the current state of the workplace.

Standardized work tools increase efficiency by identifying the value and waste in a process. Typically, people define efficiency as:

| Efficiency = Output ÷ Labor |

At Toyota, reducing the workforce is the sole means of improving efficiency since the customer determines the results. Toyota subsequently transfers the available force resulting from these reductions. The following elements contribute to efficiency:

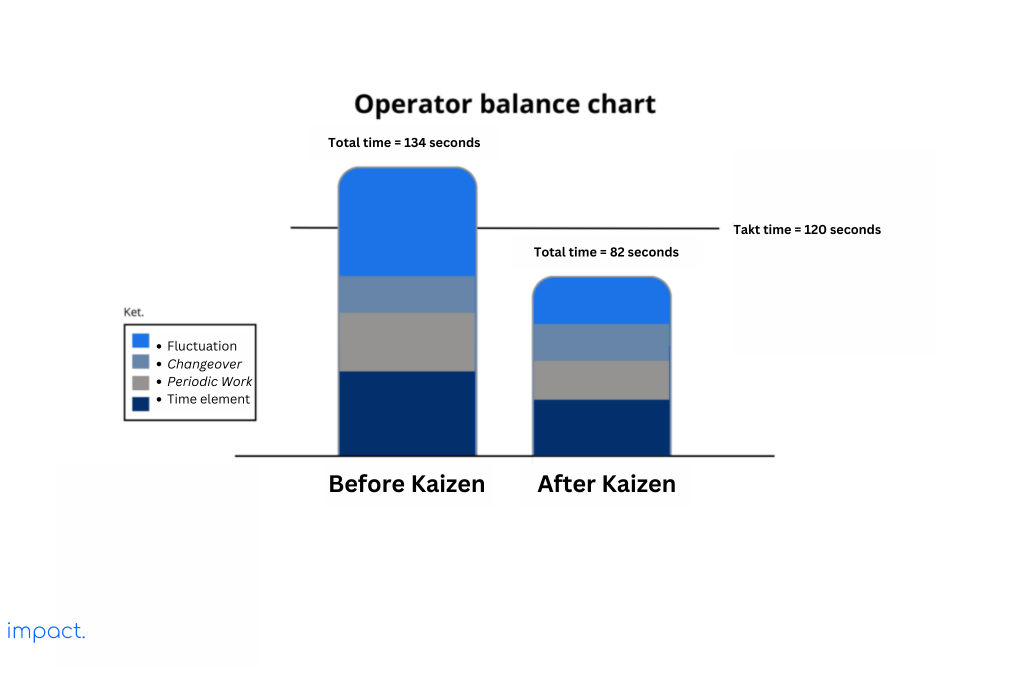

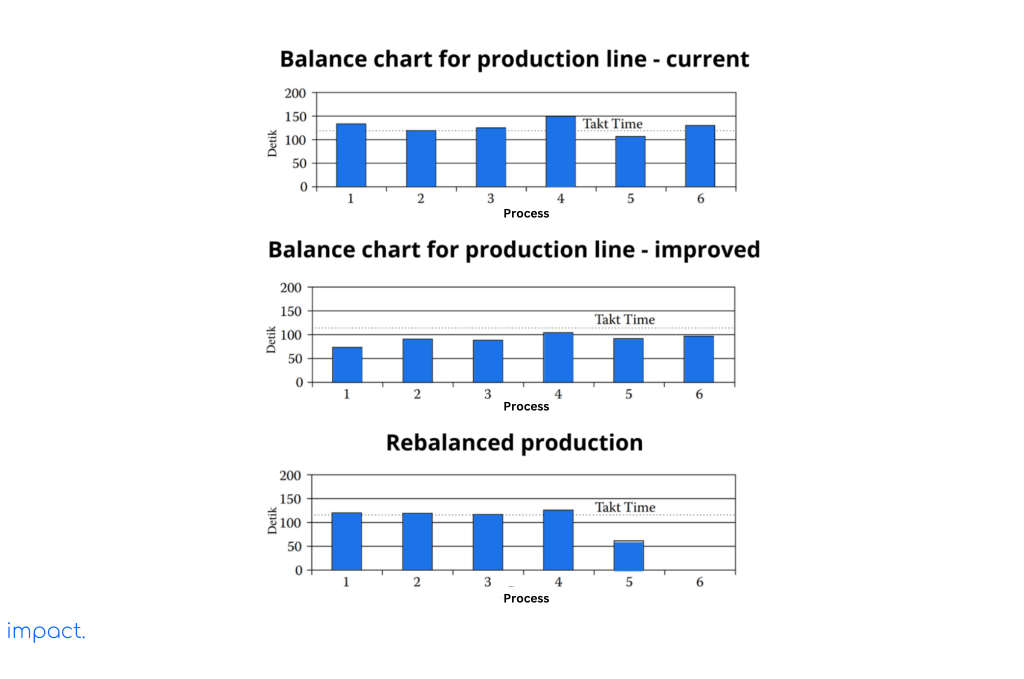

This image shows a helpful tool called an operator balance chart for pre-and post-repair processes. The improvements are due to a deep understanding of what’s happening in each process. By making changes through kaizen activity, the time for this process drops from 134 to 82 seconds. The second and third pictures display the operator balance charts for teams.

The last image shows how we can spread the work to reduce the labor needed. As you can see, we have left out process 6. Do note that processes 1 to 5 are already working at their maximum capacity, meaning they take the same amount of time as the pace of production.

However, process 5 takes up about half of the takt time. By rearranging things, we can show how long it takes to complete tasks and inspire kaizen.

| The remainder in # operatorsrequired calculation | Target |

| < .3 | Minimize wastage and incidental work. Avoid adding extra operators. |

| .3 – .5 | Evaluate whether the waste and incidental work can be eliminated after two weeks of operation and kaizen. Do not add operators. |

| > .5 | If necessary, add more operators and continue minimizing waste and incidental work to eliminate the requirement for operators. |

The image above is a guideline for determining the required number of operators.

Standardized work plays a crucial role in developing an efficient process overall. It enables us to outpace neighboring methods, resulting in a young inventory as work-in-progress builds up ahead of slower processes.

However, specific processes are inherently easier to perform than others. So, how can we foster cooperation between processes in production areas? The solution lies in designing standardized work specifically for production areas. Some key areas to focus on include:

Organizing work like this improves efficiency. The processes in a manufacturing plant rely on each other and can be affected by unpredictable changes. In “The Goal,” Eli Goldratt vividly shows the challenges faced by this kind of system:

Goldratt emphasizes the importance of identifying, exploiting, and raising bottlenecks. We can effectively reduce bottlenecks by organizing processes to encourage team members to assist each other.

Standardized work is crucial for achieving kaizen. It focuses on continuous improvement through small but sustained positive changes that can lead to significant improvements.

Failure to update standardized work can result in setbacks. It is the leader’s responsibility to uphold favorable conditions. Addressing excessive workload and irregularities (mura) becomes imperative. The following section explains these targets and their significance.

Commonly used layouts in standardized work include:

Process islands are separate from each other. Forklifts move stacks of inventory between islands. Workers in each area often focus on building quickly without considering the demand.

Conveyors or parachutes connect the islands, but there is no way to control the inventory on the conveyor. Workers typically construct as quickly as possible.

Conveyors or parachutes link the islands. Visual tools keep track of inventory between processes. The upstream process stops making more when the downstream process is already complete.

The machines are positioned side by side with minimal inventory between them. The goal is to create one section at a time. Once a piece is processed, it immediately moves to the following process. The four situations depicted in the following images illustrate this workflow.

Standardized work identifies muda and involves team members to drive development. It differs from lean production and engineering methods in its approach.

Companies can boost labor density by increasing value-added work through standardized work. The ultimate aim of standardized work is kaizen.

The next chapter will examine another pillar of the House of Lean Production — Just-in-Time (JIT). We’ll cover JIT’s definition, principles, and operations.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

See how our ERP provides better value.

Speak with our consultant to explore how we can improve your accounting, processes, and people.