12 Vital Retail Metrics & KPIs for Your Business Success

Our retail guide’s last chapter explored ways to boost your store’s success through innovative finance,…

Sean Thobias

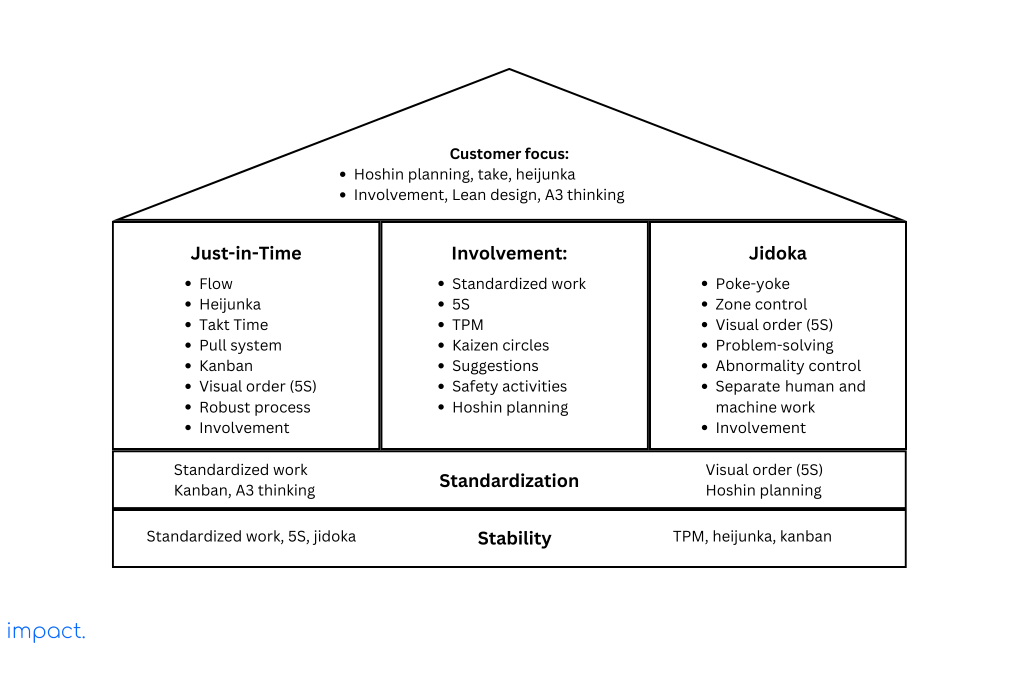

November 19, 2024This chapter discusses another House of Lean Production component: the pull system. As explained in the previous chapter, the pull system is critical in achieving Just-in-Time.

The pull system is a way to control production that helps prevent making too much stuff. It’s one of the main parts of a complete Just-in-Time (JIT) production system, along with Kanban and Heijunka.

In a pull production system, the downstream operations (either in the same or different places) let the upstream operations know what parts or materials they need, how many they need, and when and where they need them. The upstream supplier doesn’t make anything until the downstream customer says they need it.

Now, let’s learn more about the pull system, including what it is, the different types, and the benefits it brings.

The pull system is a technique used in Lean manufacturing to minimize waste in production. By implementing a pull system, companies can start producing a new item only when there is customer demand. The system helps companies reduce costs and better use their storage space.

Apple is an excellent example of how the pull system can be effective. When Apple releases a new product, they create excitement, and customers eagerly buy their products. Apple waits to see how much demand there is; if it’s high, they make more of the product. The level of demand helps Apple use its resources efficiently and operate more effectively.

Read more: Lean Manufacturing: Definition & 3 Advantages to Utilize

The pull system is a crucial principle of lean manufacturing developed in the late 1940s. It aims to establish a workflow where work starts only upon customer request rather than relying on estimates. By doing so, companies can effectively eliminate waste in the production process and minimize the risk of overstocking.

Furthermore, implementing a pull system enables companies to adopt the Just-in-Time (JIT) approach discussed earlier. JIT is a production model focusing on producing goods to meet actual demand and avoiding excessive production.

In pull systems, companies make and distribute products according to customers’ wants, not based on guesses. They only produce what is needed when it’s needed. This method is best for products with low demand or when it’s more expensive to deal with extra inventory compared to the benefits of excess stock.

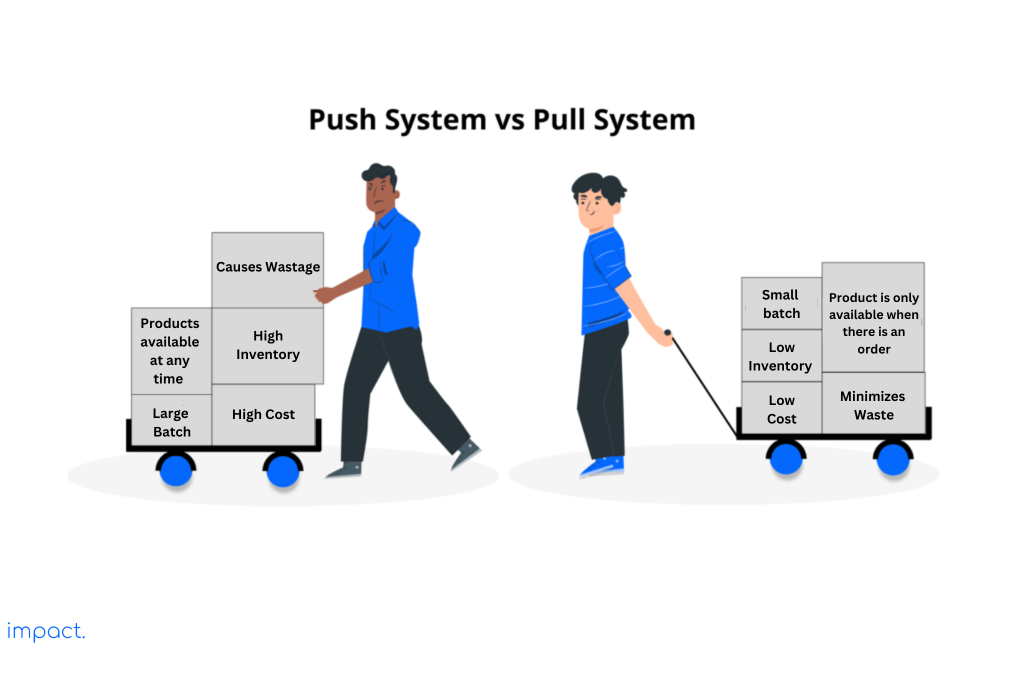

In contrast, push systems rely on estimates of customer demand to determine production. Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that demand.

Several factors set these two production systems apart. Here are some of them:

Producers can adopt a hybrid approach combining both systems to achieve mass customization. They can employ the push strategy to stockpile standard products without modifications. Then, towards the end of the production process, they can introduce the pull element, wherein the final adjustments are made based on customer orders.

Selecting the appropriate pull system is crucial when implementing lean manufacturing. Below, we will explain the three types of pull systems:

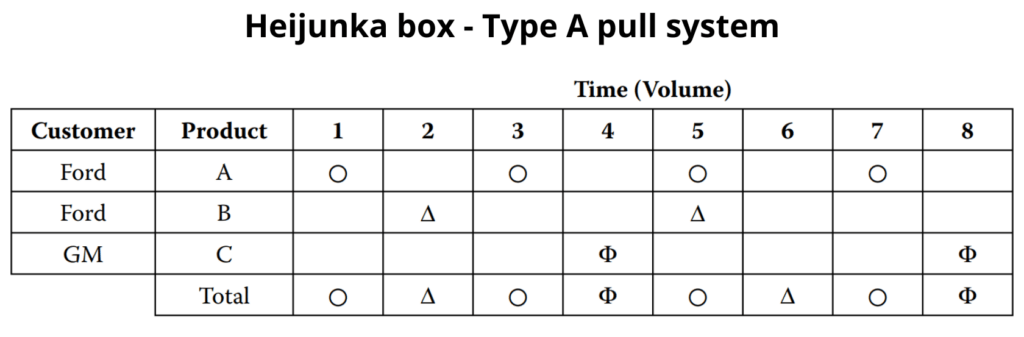

The type A system, or the Pull System supermarket, is the most commonly used one. Each process has a shop or supermarket holding the company’s products in this type. The company performs production activities to restock the supermarket based on customer demand.

When a customer takes something from the supermarket, a special Kanban card allows production to fill the space. The Heijunka box helps plan the manufacturing process by deciding the order and amount of products needed. The quantity produced depends on the demand and how much customers are taking. In type A, the number of products made by the factory and the time it takes to make them determine the rows and columns of the Heijunka Box.

Source: Dennis, P. (2017). Lean production simplified; Type A pull system.

The type A system works best when frequent customer orders and a short and stable waiting time is needed, like in the car parts industry. It requires having enough finished goods and work-in-progress supplies. The challenge for Type A is strengthening its ability to reduce inventory continuously.

Companies use the Type B or Sequential Pull System when they have low orders and customers have to wait for their orders, such as in custom producers.

Work progresses in a specific order in this system through the FIFO (First in, First Out) pathway. Kanban cards are used to authorize and determine the production sequence through the Heijunka Type B box, also called the sorting box. The company must maintain the order in which they perform and control the work released at each step to ensure a smooth flow in the customs process.

The Type B system avoids stockpiling a large number of finished goods. Instead, it emphasizes the need to maintain short and predictable waiting times. Understanding customer order patterns becomes crucial for the effective functioning of this system. When orders are challenging to predict, minimizing the waiting time for production (less than the time taken) or ensuring adequate storage of finished goods becomes necessary.

The challenge with the Type B system is that it requires strong management to keep it running smoothly, and improving it can be a challenge on the factory floor.

The Type C system combines types A and B, working together. System A handles high-frequency orders, while System B handles low-frequency orders. The Kanban card uses type A and B heijunka boxes to authorize and process orders.

Each type of pull system has its own set of requirements. The Type C system is ideal for manufacturers who produce items with both high and low frequencies.

By using both types selectively, the Type C system allows you to take advantage of the benefits of each approach. You can run these two systems side by side or use them for specific part numbers at different locations.

However, hybrid systems can make balancing work and identifying problems harder. It can also be more challenging to manage and improve processes. So, it’s essential to have discipline and make the combination system work effectively.

Various industries widely use the pull system, including manufacturing, software development, and customer service. It allows professionals to prioritize tasks and prevent team overload in workflow management.

Workers can pull their next task if they can start working on it in a pull system. The system enables better task prioritization and helps the team focus on delivering important work on time.

To achieve higher levels of productivity and workflow efficiency through a pull system, companies must:

Companies should use pull signals to improve their workflow. The easiest way to do this is by creating a visual system that records and tracks essential information. This initial step will help companies understand their work processes better and catch all the critical signals.

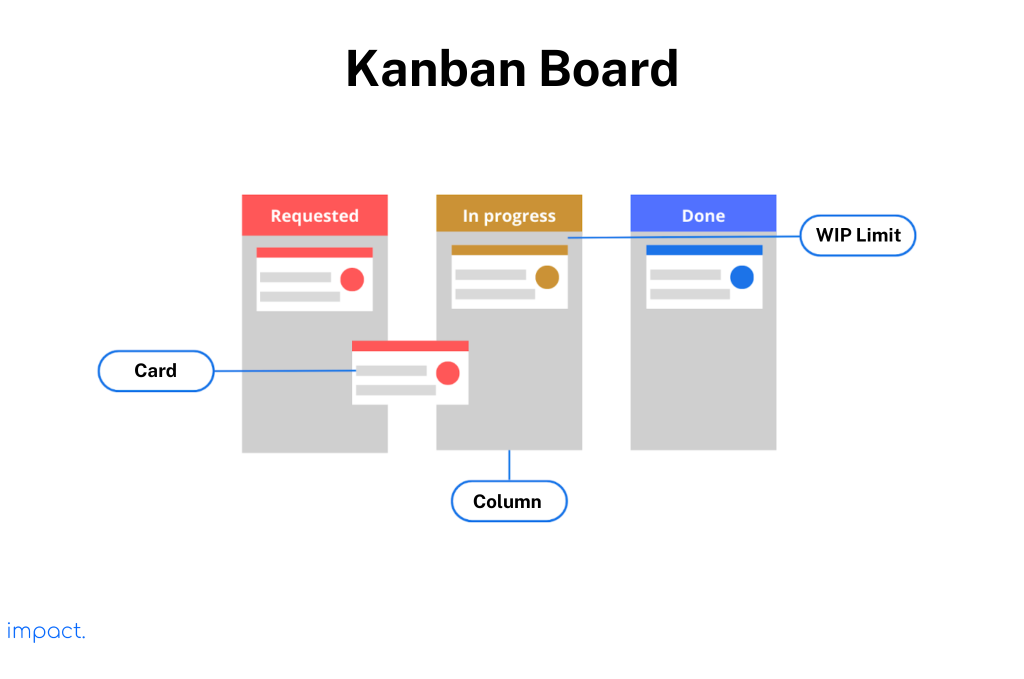

To effectively control a visual pull system, it is crucial to know how to manage it. Limiting work in progress (WIP) is a widely employed approach to handle a pull system effectively, and it stands as one of the fundamental practices of the Kanban method.

Limiting the work on a Kanban board allows for a smooth workflow and easy identification of problematic areas. Kanban boards divide workflow into requested, in-progress, and done stages.

Contrary to the common belief that multitasking increases productivity, limiting the work in progress (WIP) keeps team members focused on a single task until completion.

When focused, your team can achieve excellence and deliver work faster. However, limiting the WIP is insufficient for establishing a continuous pull system. Setting time limits for each task in your system is also crucial.

The time limit may vary depending on the task’s size and serves as a requirement. Neglecting to enforce time limits can result in jobs taking excessive time in the process and decrease flow efficiency.

Read also: Kanban: Definition, 6 Rules, and its Benefits

Pull systems are superior to push systems because they enable team members to concentrate on one task at a time. This approach offers several benefits:

Furthermore, employing the pull system principle enables you to enhance the predictability of your future work. Pull systems empower companies to accumulate historical data on workflow and average task cycle times, fostering a more informed planning process.

The pull system is an integral part of Lean manufacturing. Its main goal is to create a workflow where work begins only when the customer requests it. When implementing the pull system, it’s essential to understand how it differs from the push system. Pull systems generally have three types: A, B, and C, each with advantages.

After discussing pull systems, the next chapter will focus on Value Stream Mapping. This chapter will explain what it means, how it works, and the benefits it provides.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

Contact us to get complete ERP features comparison of top 7 ERP systems in Indonesia.