12 Vital Retail Metrics & KPIs for Your Business Success

Our retail guide’s last chapter explored ways to boost your store’s success through innovative finance,…

Sean Thobias

November 19, 2024The inventory turnover ratio is a crucial metric in retail, helping businesses gauge their operational efficiency. It shows how fast a company sells and replenishes its inventory, providing insights into its health.

This article delves into the significance of the inventory turnover ratio, explaining its definition, calculation methods, and impact on a company’s success. Beyond financial aspects, mastering this ratio is vital for profitability, customer satisfaction, and staying competitive in the industry.

Inventory turnover is a tool that shows how well a company handles its stock by revealing how often it sells and replenishes it. This ratio is vital for businesses dealing with tangible goods as it gauges the success of their inventory management.

Businesses can use the inventory turnover ratio to improve their pricing, manufacturing, marketing, and purchasing strategies. An efficiency ratio tells us how well a company utilizes its assets.

A high inventory turnover means your products are selling fast, turning inventory into cash quickly. This improved cash flow helps you invest in your business, pay off debts, and seize growth chances, ensuring a healthy financial situation.

Rapidly selling goods is crucial for maintaining good cash flow, preventing tied-up capital in slow-moving or excess inventory from affecting your ability to meet financial obligations.

Businesses usually need a place to keep their stuff before selling it. If you have a warehouse or a particular area for your things, you’re spending money to keep them there.

Inventory turnover is about lowering the costs of keeping stuff in your storage. The longer things stay in your warehouse, the more you pay for storage and insurance, and the more risk there is of them becoming outdated.

Maintaining a high inventory turnover rate ensures that products are always available for customers. By keeping a close eye on turnover, you ensure popular items stay in stock, reducing the chances of running out and improving your ability to meet customer demand quickly.

Effective inventory management boosts profits by reducing excess inventory costs. Streamlining inventory turnover can also empower businesses to negotiate better terms with suppliers, resulting in discounts and favorable payment options that enhance profitability.

Understanding inventory turnover is crucial for intelligent business choices. Quick adjustments are necessary for shifting consumer tastes, market trends, or economic fluctuations.

A higher inventory turnover ratio helps companies respond promptly to market shifts. It enables them to adapt real-time production, pricing, or marketing strategies according to the demand for their products.

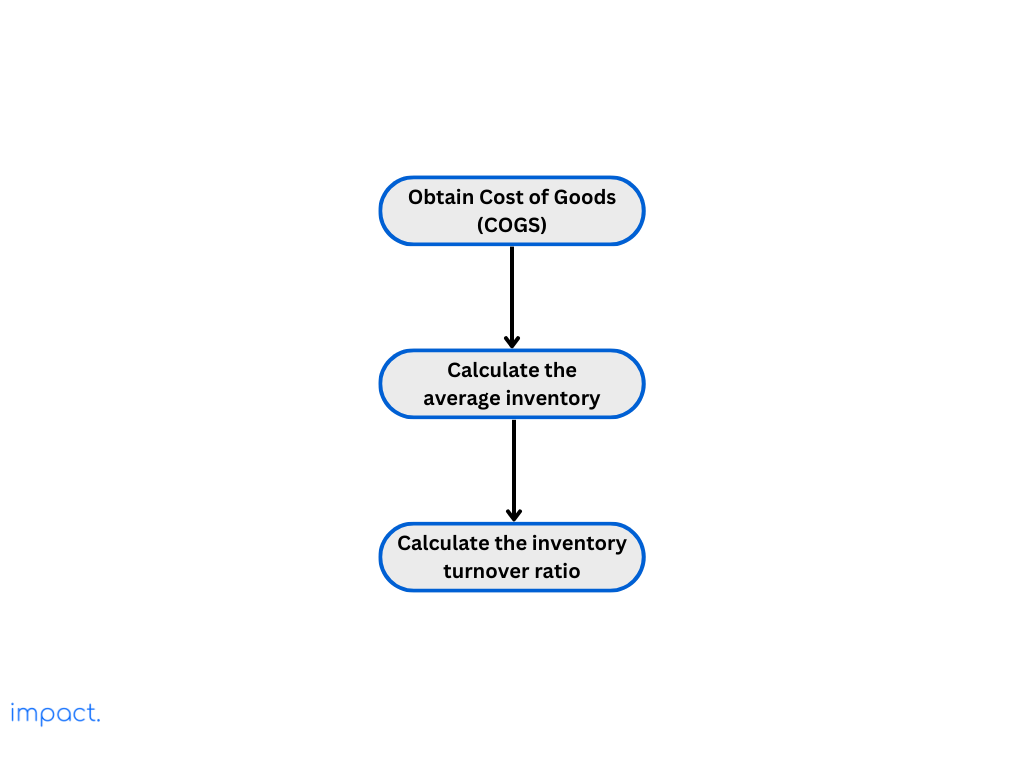

COGS, or Cost of Goods Sold, appears on the income statement. It covers the direct expenses of making or buying resale products, excluding indirect costs like distribution and sales force expenses.

In simple terms, you spend COGS directly to produce the product. For retail businesses, it’s usually the cost of the finished product (plus shipping, if applicable) bought from a manufacturer or supplier.

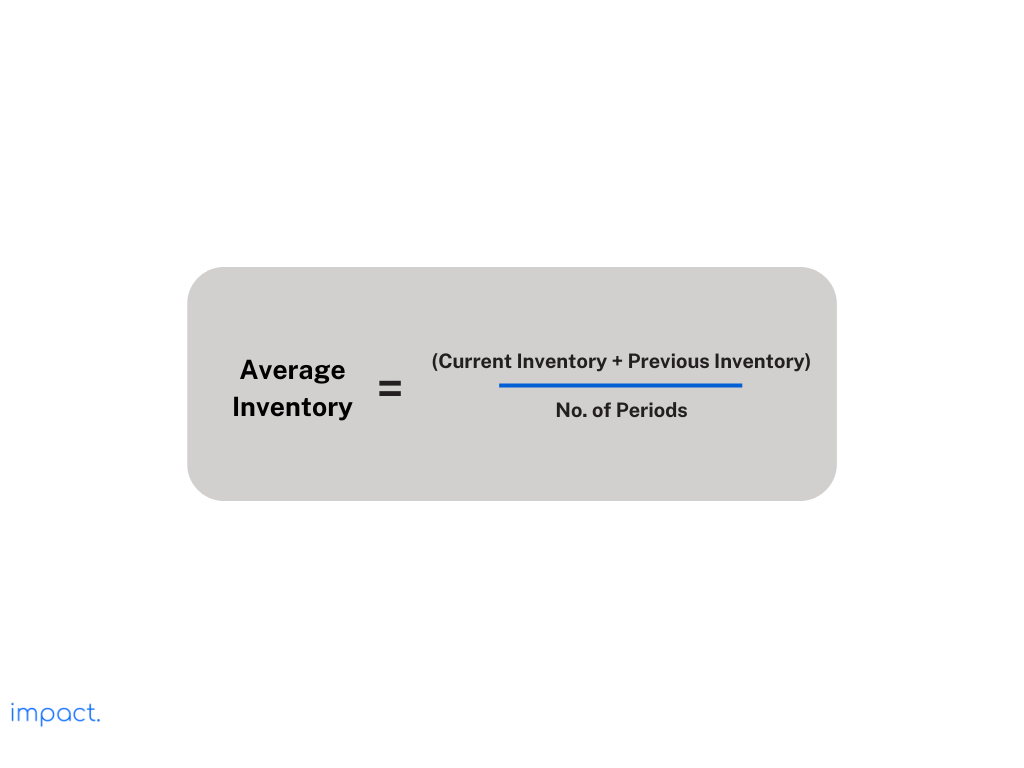

Average inventory is a way to determine the approximate value or quantity of goods during specific time frames. It’s the average value of inventory within a set period, calculated by adding the starting and ending inventory values and dividing by the time period.

You can use this formula for extended periods, such as totaling monthly inventories for a year and dividing by 12. It’s also applicable to shorter timeframes, like averaging the beginning and end of the month’s inventory and dividing by 2.

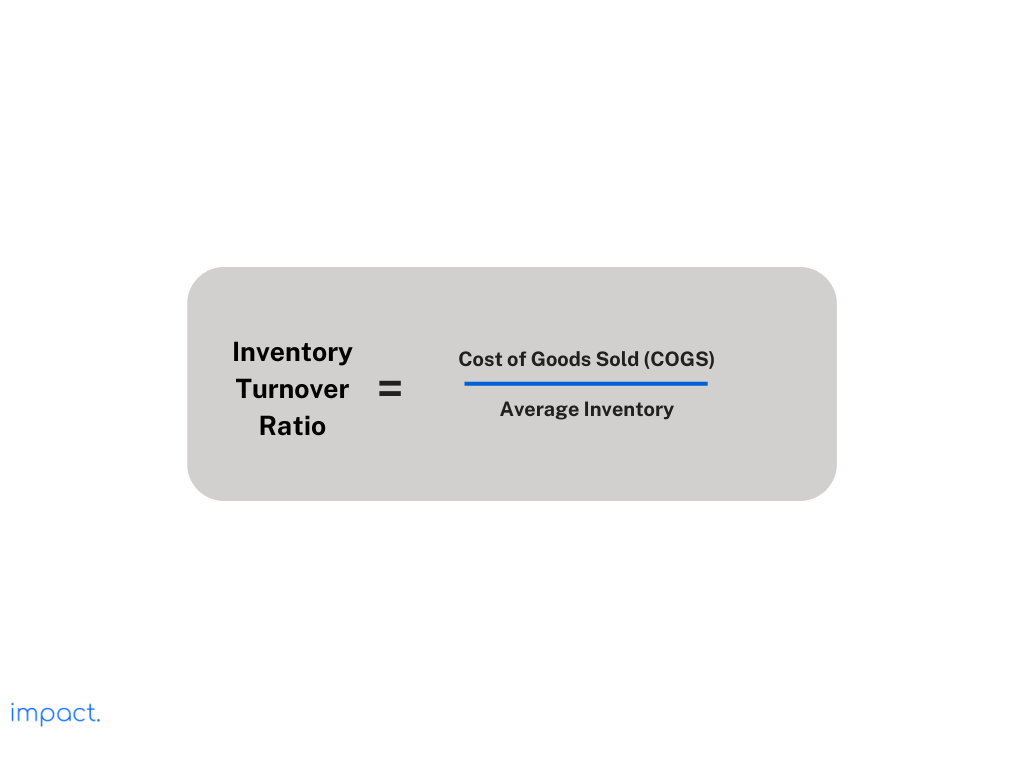

With the Cost of Goods Sold (COGS) and Average Inventory on hand, you can easily find the Inventory Turnover Ratio using the following formula:

The best inventory turnover ratio varies by industry, and what’s “good” depends on the type of business and its products. Generally, a higher ratio is better because it shows the company is efficiently handling its inventory and turning it into sales quickly.

A high ratio means the company sells products fast and manages stock well, reducing the risk of unsold items. However, a high ratio may signal problems like stockouts, leading to lost sales. On the other hand, a low ratio might mean too much stock or slow-moving items, tying up money and raising holding costs.

Read more: Warehouse Management: Significance in Supply Chain, Challenges & Success Factors

Keeping your inventory turnover healthy is essential to handle minor changes without big problems. However, the impact can be significant regarding time-based ups and downs, like during holidays and seasons.

Before a season, inventory turnover goes up, stays steady during the season, and drops after it ends. Good planning and intelligent inventory management can help reduce the harmful effects of seasonality on turnover rates.

Inventory shifts as products go through their lifecycle. Turnover rates rise during the introduction and growth stages, hitting their highest point in the maturity phase.

However, as market saturation and evolving customer preferences lead to declining inventory sales, adjusting pricing and promotions can help bring inventory turnover back to healthier levels.

Building solid relationships with suppliers is essential for a smooth supply chain. Reliable suppliers help ensure consistent and timely deliveries, cutting down on lead times and allowing businesses to manage their inventory more efficiently, positively impacting turnover.

Good inventory management is all about how well the inventory department handles items. If turnover rates are too high or too low, it’s a sign that we need to check and improve our ordering and management methods.

Effective inventory management involves accurate record-keeping, real-time tracking, and strategic ordering to ensure smooth stock movement and avoid overstocking or understocking.

Efficient warehouse operations are crucial for speeding up the supply chain. A well-organized layout, smooth order picking and packing, and intelligent inventory rotation all help products move faster. This efficiency reduces unnecessary costs and reduces the time products stay in storage.

Read more: The Ultimate Guide to Choose the Right Warehouse Layout and Design

Automating tasks boosts efficiency and can save costs. Use an inventory management system that updates stock in real-time and notifies you instantly when a sale occurs.

Choose a system that swiftly and accurately fulfills purchase orders for better control and fewer errors. Additionally, set up reorder point alerts to ensure timely restocking, minimizing the chances of stockouts and overstock situations.

One-size-fits-all pricing strategies won’t cut it. Instead, use different approaches like bundling, discounts, or promotions to boost sales and clear inventory.

Optimize pricing to maximize profits for popular items and eliminate outdated inventory. If certain items aren’t selling, consider donating them for a tax deduction or selling through alternative channels.

To make the supply chain smoother, focus on improving everything from buying to delivering. Cut down on waiting times, work with fewer suppliers, and use effective logistics to lower storage costs and speed up product movement.

Don’t just pick suppliers with the cheapest prices; work together to set up fast and reliable delivery plans. Especially for products crucial to your inventory sales or facing high demand, prioritize quicker or guaranteed delivery for those items or essential parts.

Different products have different levels of popularity, affected by seasons, occasions, and fashion trends. To stay on top of this, regularly monitor and adjust your yearly and quarterly forecasts based on these factors and your target audience.

By employing advanced forecasting methods like data analytics and machine learning, businesses can enhance their ability to predict future demand. Forecasting reduces the chances of running out of stock or having excess inventory, ensuring your stock turnover aligns with actual demand trends.

To boost your inventory turnover, create a strong marketing plan. Target low-selling items and connect with hard-to-reach customers.

Expand into new markets and utilize various marketing channels like social media, SEO, paid ads, content marketing, and email campaigns to enhance sales and improve your inventory turnover rate.

The inventory turnover ratio is vital, showing how well a company handles its stock. Keeping a good turnover ratio isn’t just about finances; it’s a smart strategic move.

Integrating inventory management software with an ERP system helps businesses simplify and automate inventory tasks, making calculating and improving turnover ratios easier. By using these tools and practicing efficient inventory management, companies can boost financial performance, satisfy customers, and navigate the ever-changing world of commerce.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

75% of digital transformation projects fail. Take the right first step by choosing a reliable long-term partner.