Retail Inventory & Pricing: a Management Guide

Overview As your retail business evolves with a chosen location and a well-designed interior, the…

Sean Thobias

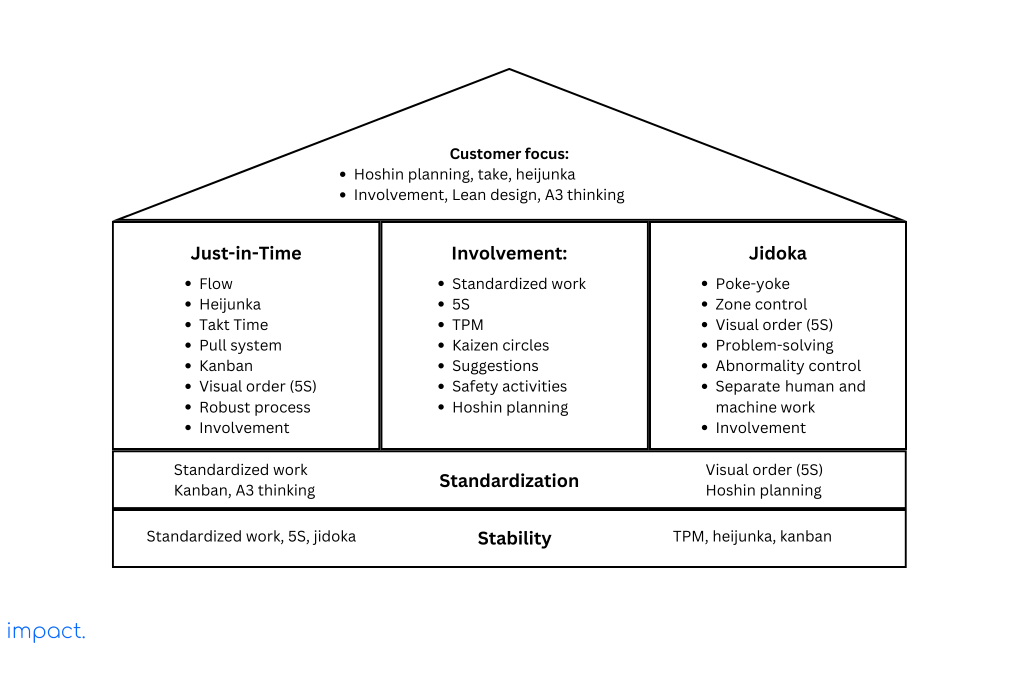

December 12, 2023Poka-yoke is a vital part of Jidoka in the House of Lean Production. Its main goal is to prevent errors and defects. The manufacturing industry utilizes Poka-yoke as a standardized work technique.

The main idea behind Poka-yoke is to stop errors and defects before they happen. Using Poka-yoke has proven to be highly effective in improving production efficiency in manufacturing. Now, let’s explore the definitions, benefits, and examples of Poka-yoke:

Poka-yoke is a concept from Japan. Shigeo Shingo coined the term, and it’s all about stopping mistakes and ensuring products are perfect without any problems.

The concept helps find potential defects early on by preventing different errors during production. Here are some common mistakes that often happen in manufacturing:

Poka-yoke uses machines or methods to help spot mistakes quickly. Its main goal is to ensure the production process doesn’t progress unless everything is correct.

Read more: Lean Manufacturing: Definition & 3 Benefits

When it detects an error, poka-yoke takes two types of actions: turning off the engine or giving a warning. Here’s the explanation:

Shutting down the engine is the most potent action of Poka yoke. Here are some examples:

The full-work system is another way of shutting down a process. In this system, a supplier stops providing materials to the next stage when it has reached its maximum capacity. The system operates at total capacity when it achieves the desired number of parts.

The Poka yoke warning system sends out an alert when something goes wrong. It does this by making a buzzer or light go off. A well-known example of this is the andon board used by Toyota. It lets the group leader know when there’s a problem by showing the process number, playing music, or sometimes both.

In Toyota’s case, team members activate the andon by pulling a cable along the production line. The line keeps moving until it reaches a specific spot. Since each step in the process has its own fixed location, team members can finish at least one cycle of work. Stopping the line during an operation reduces the chances of making mistakes.

Poka-yoke detects deviations in the workpiece or work method through the following ways:

This method employs sensing devices to identify product weight, dimensions, or shape abnormalities. Here are some examples:

This Poka-yoke method uses sensors to find mistakes in everyday actions. For example, a counter actively tracks the number of weld points on the workpiece. The clamps stay locked until reaching the correct number of weld points. This way, the work arrangement ensures that the next step can’t happen until the completion of the previous phase.

Counters play a crucial role in this scenario. They offer valuable utility, such as:

Sensor technology constantly evolves, particularly in Poka yoke. In this context, we can classify sensors into two categories: contact sensors and non-contact sensors. Now, let’s delve into a more detailed explanation:

The most common types of contact sensors are:

The device can detect interruptions in the light beam, nearby solid objects, metal tracks, fibers, color, ultraviolet light, infrared light, counting errors, electron beam, size, pressure, temperature, electric current changes, and vibration. Here are some commonly used devices:

There are two key indicators to ensure effective Poka-yoke implementation:

Implementing Poka yoke is straightforward and logical. Here are some steps for you to follow:

In the automotive and consumer product industries, the pictures below demonstrate the application of Poka yoke. The floor shop team members are the ones who came up with most of the Poka-yoke ideas.

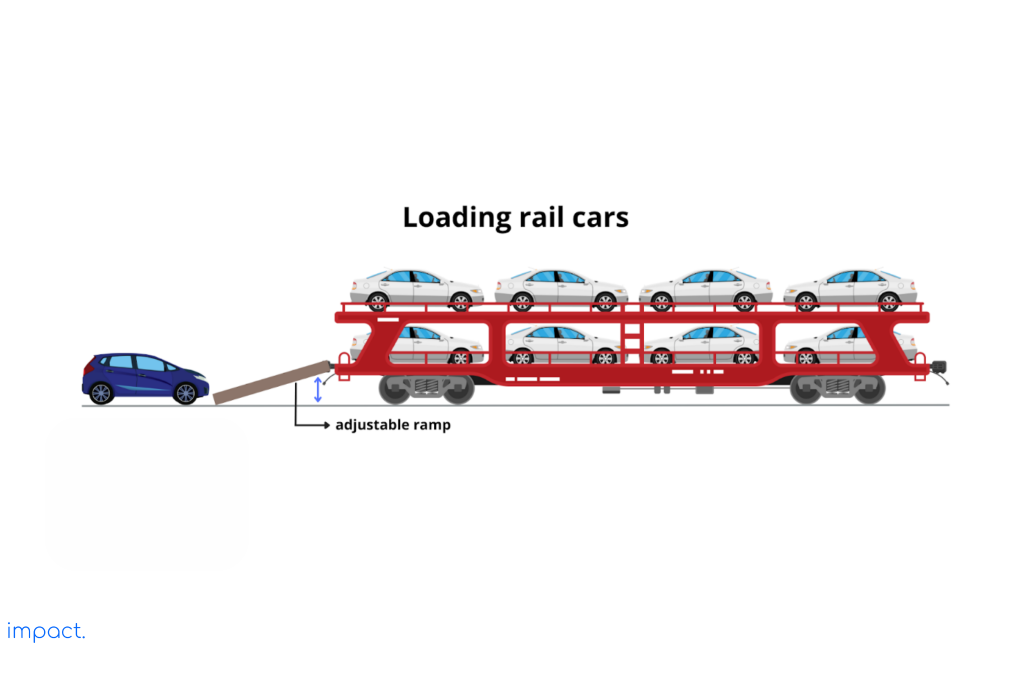

The car manufacturing industry faces challenges when loading cars into freight cars. Loading the car into the carrier proves difficult due to inappropriate height. Therefore, we need a method to prevent damage and ensure safety during car transportation.

To fix these problems, we implement Poka yoke in the following ways:

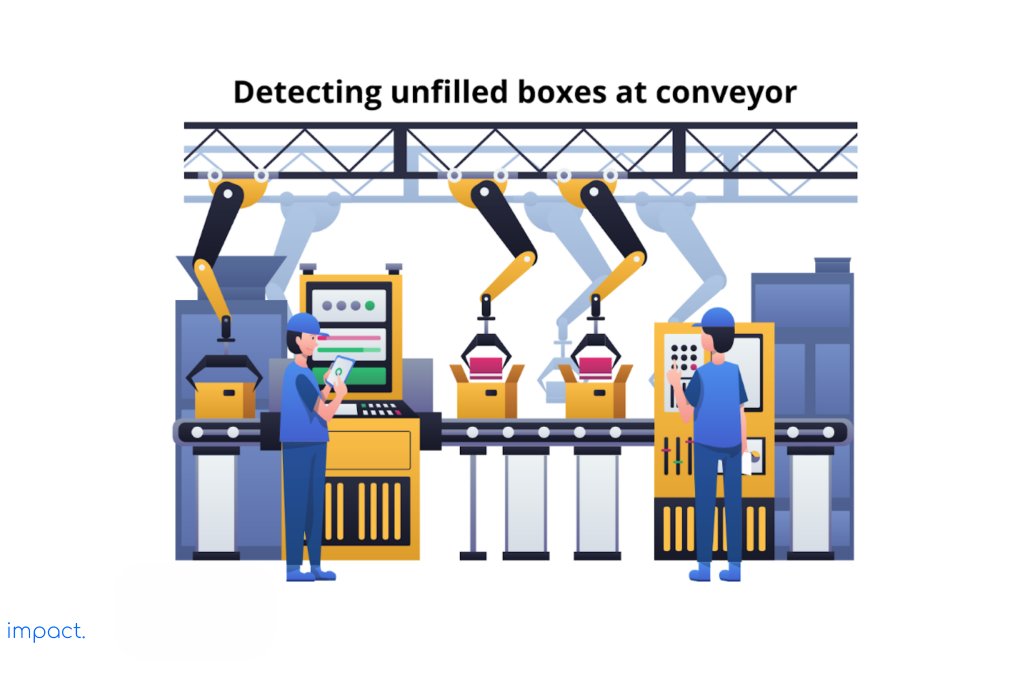

Previously, detecting unfilled boxes in the consumer product industry posed a challenge for companies. Occasionally, boxes would remain unfilled due to machine errors, yet they were still closed and sent for shipment.

To address this issue, companies employ Poka yoke through the following measures:

Read more: Jidoka: Definition and its 2 Implementation Strategies

Poka-yoke is a manufacturing method that prevents defects and errors in production. It involves two actions: stopping the machine and providing a warning in case of a mistake. Poka-yoke is commonly found in manufacturing companies that heavily rely on devices.

Having understood the concept of Poka yoke, the next chapter will discuss involvement, the core of the House of Lean Production.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

See how our ERP provides better value.

Speak with our consultant to explore how we can improve your accounting, processes, and people.