Kanban: Definition, 6 Rules, and its Benefits

Kanban is a crucial part of the Just in Time (JIT) system, which we discussed…

Sean Thobias

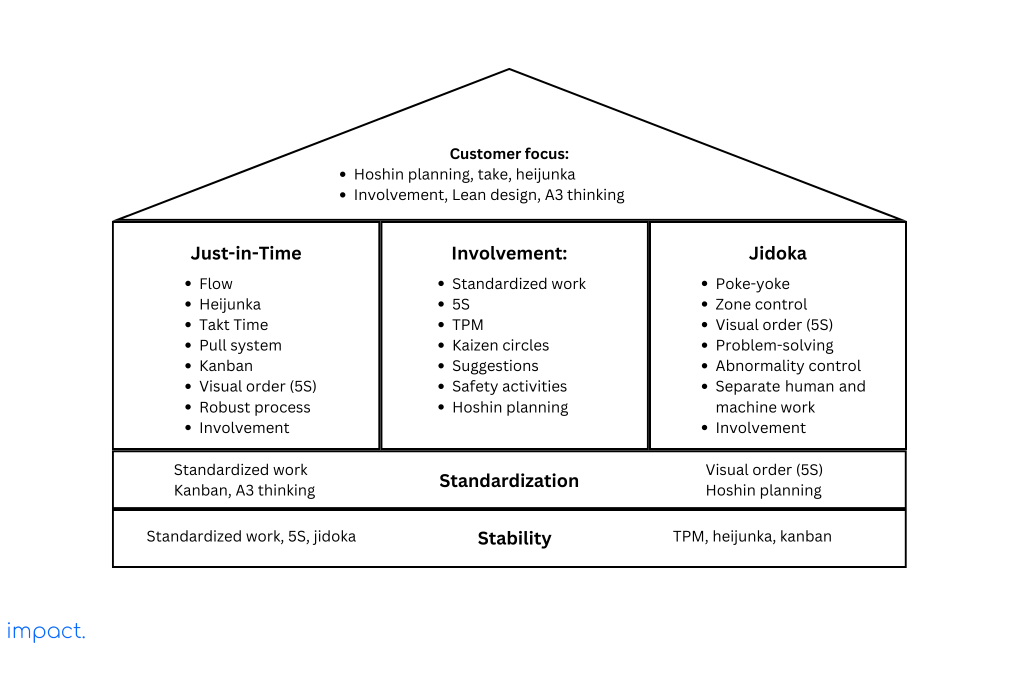

May 17, 2025Hoshin kanri, or Hoshin planning, is an integral part of the House of Lean Production that encourages employees to be involved in company planning.

Every company needs clear goals and a well-thought-out plan to achieve them. Hoshin Kanri helps companies by identifying goals, figuring out the best ways to reach those goals, and supporting the actions required.

Let’s dive deeper into Hoshin Kanri, starting with what it is and the four phases of its application.

Planning is figuring out how to gain an advantage and achieve goals by making a strategy. It involves answering two critical questions: (1) Where are we going? and (2) How do we get there?

There are four types of planning commonly used in modern organizations:

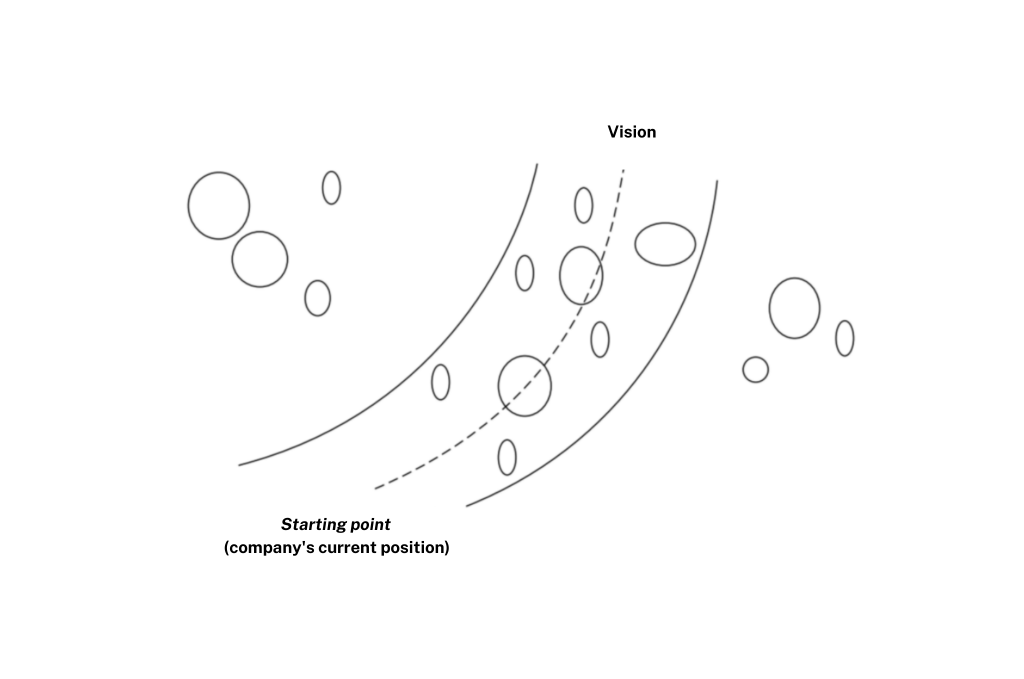

This chapter emphasizes strategic planning, focusing on goals and their methods. To create an effective plan, the company must grasp critical aspects, including its current position, the desired goals (vision), the plans to attain those goals, and potential problems and obstacles.

Here is a visualization of a company’s planning process as it progresses toward its goals:

Source: Dennis, P. (2017). Lean production simplified; Road Metaphor.

Planning is essential for companies because it helps them create a shared vision of where they want to go and how to get there. In Lean manufacturing, planning works like a pull system, where the idea is so convincing that it pulls the company into the future.

Planning also helps improve the abilities of individuals and the company. It encourages new ideas and innovation and helps the organization learn and grow.

It’s essential to consider the company’s strengths and weaknesses and take action to prevent problems for an effective plan. Planning also helps keep the company motivated by setting new goals regularly and avoiding complacency.

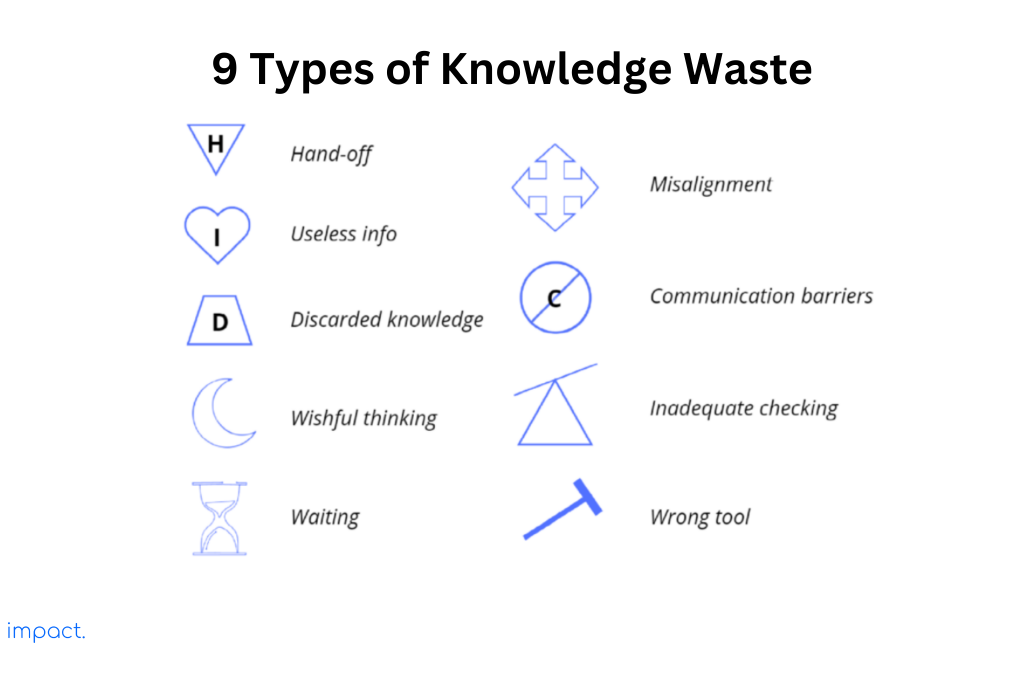

Mintzberg’s influential work, “The Rise and Fall of Strategic Planning,” reveals some problems with traditional planning. These problems include:

Planning problems often arise due to disconnections within departments (horizontal), between departments (vertical), and over time (temporal). These disconnections result in wasted knowledge and inefficiencies. The figure below displays nine symbols representing specific types of knowledge wastage.

Most companies have a lot of energy and talented people but still struggle to reach their goals. To overcome this challenge, companies can create a smooth knowledge flow, experience, and creativity within the organization.

By using Hoshin Kanri or Hoshin planning, companies can involve everyone in the company and effectively solve strategic problems.

Hoshin Kanri is how a company manages its goals and ensures it goes in the right direction. “Hoshin” means direction or purpose, and “Kanri” means management or managing. In simple terms, Hoshin Kanri is the company’s way of setting and achieving goals while staying on track.

Hoshin Kanri, also known as Hoshin planning, is like the nervous system of Lean manufacturing. It helps businesses figure out what they must do in the short-term (one year) and long-term (three to five years) to succeed. It’s all about identifying those needs and helping employees develop their skills.

To make it happen, Hoshin Kanri brings together all the company’s resources and ensures everyone is working towards the same goals. It uses a cycle called PDCA (Plan, Do, Check, Action) to keep things on track and get the results they want.

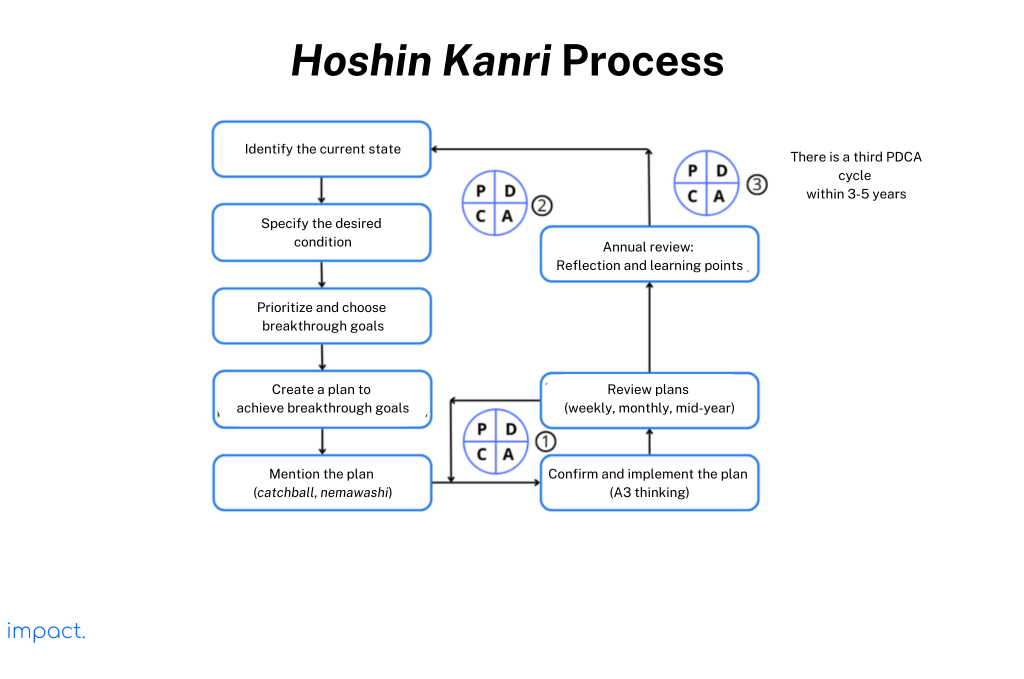

The Hoshin Kanri method follows a simple 7-step process:

Read more: Lean Manufacturing: Definition & 3 Benefits

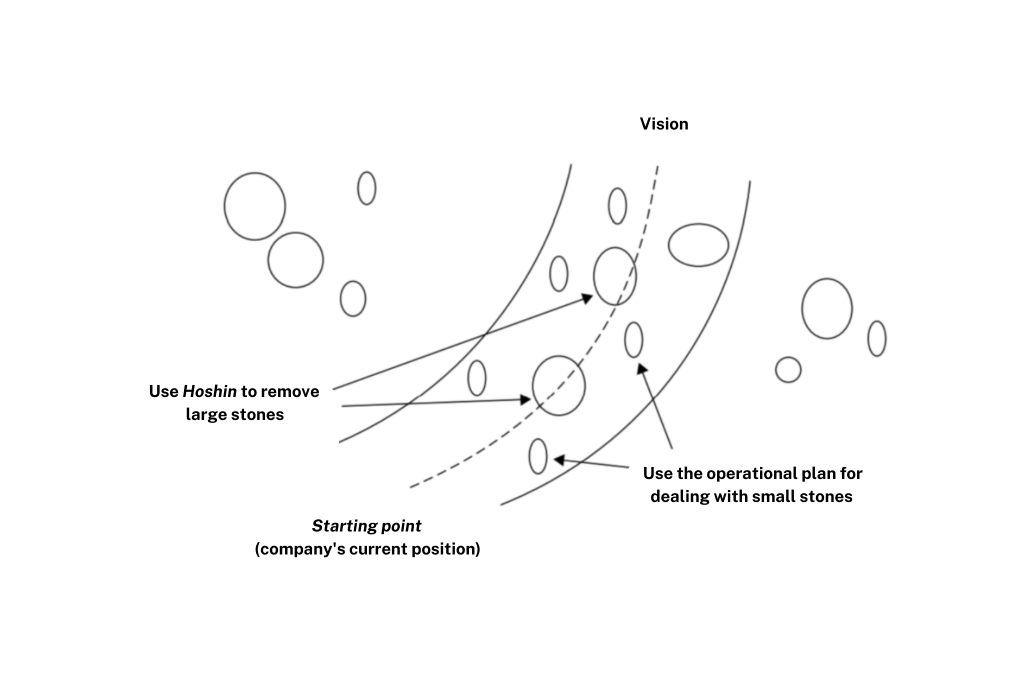

Hoshin Kanri focuses on essential issues for improvement, represented as big stones. It uses an operational plan to handle routine work like small stones. However, a common mistake in Hoshin Kanri is trying to do too much, draining energy and leading to no real achievements.

Source: Dennis, P. (2017). Lean production simplified; The road metaphor with problems targeted.

In Hoshin Kanri, companies need to align resources and promptly adapt to changes in the flexible business environment. This approach helps them stay on track and respond effectively to any shifts or challenges that come their way.

Hoshin Kanri improves upon Management by Objectives (MBO), a concept introduced by Peter Drucker in his 1954 book “The Practice of Management.” It takes MBO’s strengths and fixes its weaknesses.

Hoshin Planning system includes improvements such as Plan-Do-Check-Act (PDCA), Nemawashi, Catchball, control department concept, and A3 thinking. Let’s take a look at each of these systems:

The PDCA cycle is a crucial model in lean manufacturing for implementing changes. It provides a four-step method that helps teams improve processes and prevent repetitive mistakes. Here is a concise explanation of each PDCA step:

Hoshin Kanri incorporates multiple overlapping PDCA cycles, including:

PDCA requires a management system that shows everyone what’s going on and stops problems from happening. This system includes both formal and informal reviews.

Formal reviews should happen three times yearly: at the year’s beginning, middle, and end. The year-end review summarizes past events and assists in planning for the next year (which the management team presents in January).

Informal reviews involve the management team providing daily status reports, department heads reporting progress in weekly meetings, and conducting shop floor process reviews. These casual reviews are crucial in keeping everyone informed and detecting problems early.

Nemawashi is a way to reach an agreement and create harmony. Before putting it into action, Nemawashi involves discussing the plan with all the customers who would be affected. It also includes making changes to the program based on their feedback.

Catchball is the process of managers at different levels exchanging ideas and feedback during planning. It helps strategy and tactics to spread throughout the organization.

Catchball connects the officers’ vision with the day-to-day activities of the shop floor team members. Here’s how it works:

The control department is essential for solving the problems that many organizations face. Different groups must work together regarding important areas like productivity, quality, cost, and safety.

For instance, groups like Manufacturing, Purchasing, Production Control, Engineering, Maintenance, and Quality must collaborate to meet quality goals.

Regarding quality, the control department coordinates activities among these groups to achieve company objectives. Some of their tasks include:

A3 is a way of thinking based on PDCA, nemawashi, and catchball. A good A3 shows that you understand the situation well and know how to use Lean tools effectively.

An A3 report is a simple one-page document printed on 11″×17″ paper. Toyota started using A3 in the 1960s to summarize the Kaizen Circle Activity (KCA), and it has become Toyota’s most helpful communication tool.

There are four types of A3 documents:

The main challenge in writing A3 lies in the varying report formats employed across different departments or sections. Another issue is the “better by the pound” syndrome.

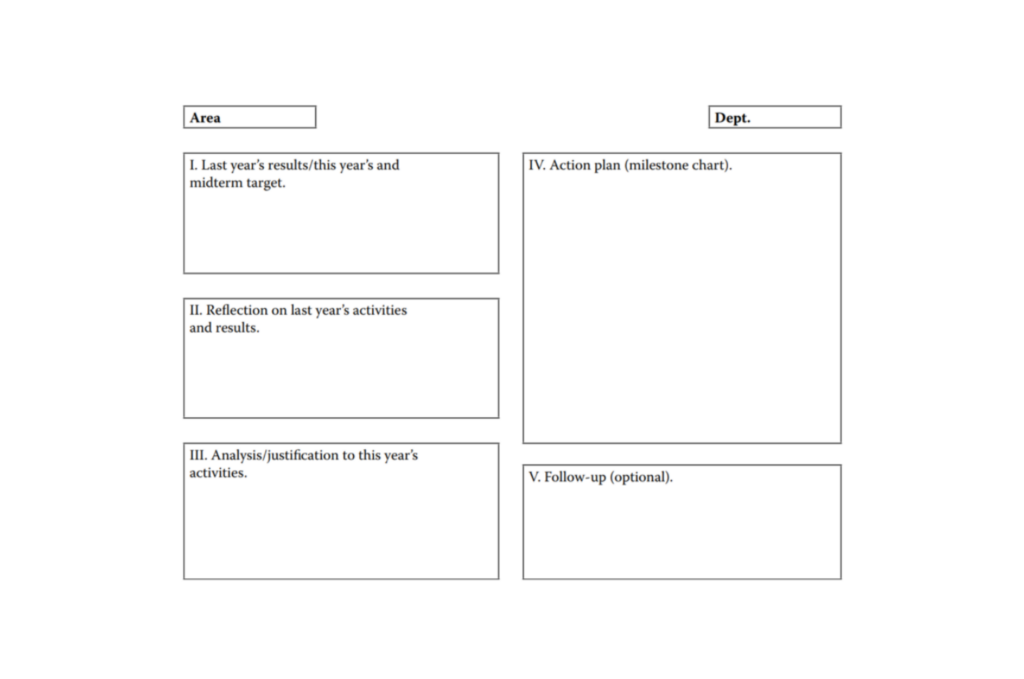

Take a look at the image below. It shows the format of the Hoshin Kanri A3, which is essentially a storyboard following a standard and logical structure. You can adjust the layout to show the current situation or address any problems.

Source: Dennis, P. (2017). Lean production simplified; Hoshin Kanri A3.

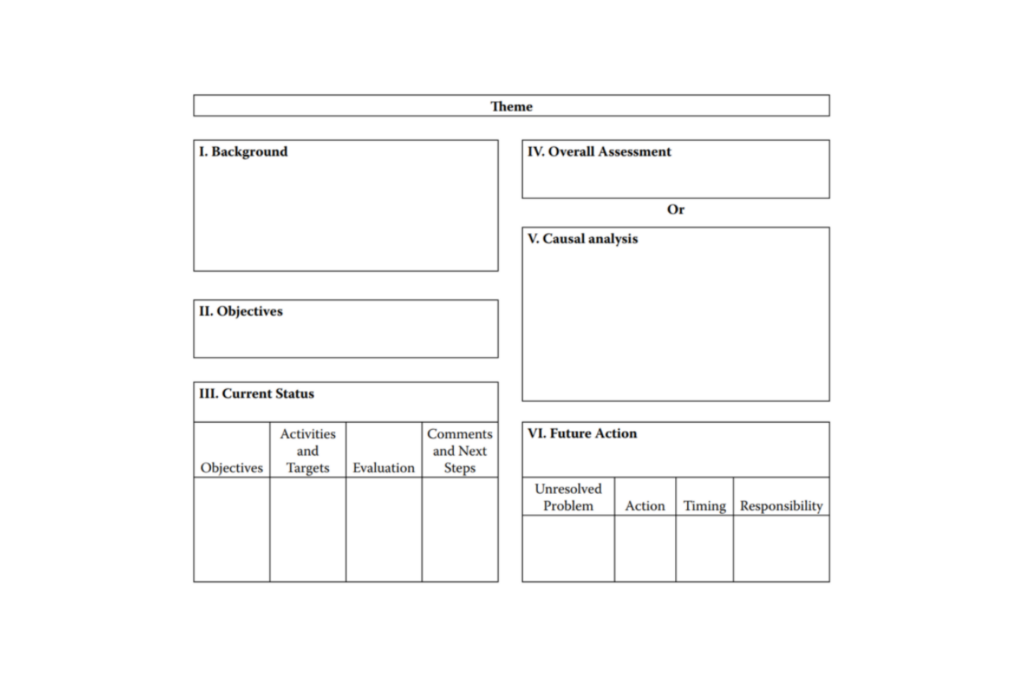

The image below displays the current A3 status format for reporting hoshin progress.

Source: Dennis, P. (2017). Lean production simplified; Current status A3.

Hoshin Kanri consists of four phases: Hoshin generation, Hoshin deployment, Hoshin implementation, and final evaluation. Let’s break down each stage and see what it involves.

The first step is called “hoshin generation,” where the company sets its annual and departmental goals. Senior management collaborates with subordinates to discuss processes and outcomes to achieve this.

Let’s examine how we can apply this first step in the quality department. The goal is to reduce the overall damage rate by 20% before the year ends. We will achieve this by:

In this phase, you must set specific goals and plans at different levels within and across departments. To accomplish this, teams should discuss and share ideas (nemawashi and catchball). At each station, the focus should be on converting hoshin goals and means into practical actions.

For example, the assembly department wants to reduce defect rates by 25%. To achieve this, they will:

When you implement hoshin, you’ll get results like tree and affinity diagrams and the A3 strategic plan. These things are developed step by step through listening to everyone’s input.

In the first year of hoshin planning, each level typically takes around two weeks to reach an agreement and create a shared strategy in A3 format. However, as you move into the second year, the process becomes faster and can be completed more quickly.

This phase is about putting the developed hoshin into action through management activities. It includes carrying out several PDCA cycles. Throughout the year, there should be formal and informal reviews to keep track of the current status and countermeasures.

In the year-end assessment of each hoshin kanri, we determine if we achieved the process and outcome objectives. We analyze what we learned and identify ways to strengthen our abilities. By answering these questions, we can evaluate whether Hoshin Kanri has been implemented effectively or requires improvement.

A learning organization is about improving our actions by gaining better knowledge and understanding. It means constantly learning and growing to make our efforts more effective.

Hoshin Kanri is an integral part of Lean manufacturing that involves everyone in the company working together to create strategic plans. It helps align resources and goals effectively.

The Hoshin planning system includes PDCA, catchball, nemawashi, the control department concept, and A3 thinking. Hoshin Kanri has four phases: development, deployment, implementation, and evaluation.

In the upcoming chapter, we will delve into Lean Culture.

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

See how our ERP provides better value.

Speak with our consultant to explore how we can improve your accounting, processes, and people.