Best ERP Software for Indonesian Businesses in 2025

There is no such thing as the best ERP software. ERP exists to automate and…

Nindy

July 9, 2025An ERP system is an integrated software used by different teams to automate core business processes.

| Module | User | Purpose |

| CRM | Sales team | Manage customers and pipelines |

| Sales | Sales team | Manage quotations and sales orders |

| POS | Stores | Automate sales transactions and payments |

| MRP | Production team | Production and raw materials planning |

| MES | Production team | Manage bills of materials and manufacturing orders |

| Inventory | Warehouse | Planning and manage receiving and delivery orders |

| WMS | Warehouse | Manage inventory receipts, picking, and packing |

| Purchase | Purchasing | Manage purchase requisition, purchase orders, tender process |

| Accounting | Accounting | Automate journal entries and produce real-time reports |

Common add-ons:

| Module | User | Purpose |

| Website builder | Marketing team | Create and manage online stores |

| MRP | Production team | Production and raw materials planning |

| MES | Production team | Manage bills of materials and manufacturing orders |

| Project | Project team | Manage projects, budgets, and tasks |

| Omnichannel | Sales team | Consistent customer experience across different channels |

| HR | All employees | Automate HR administrative works |

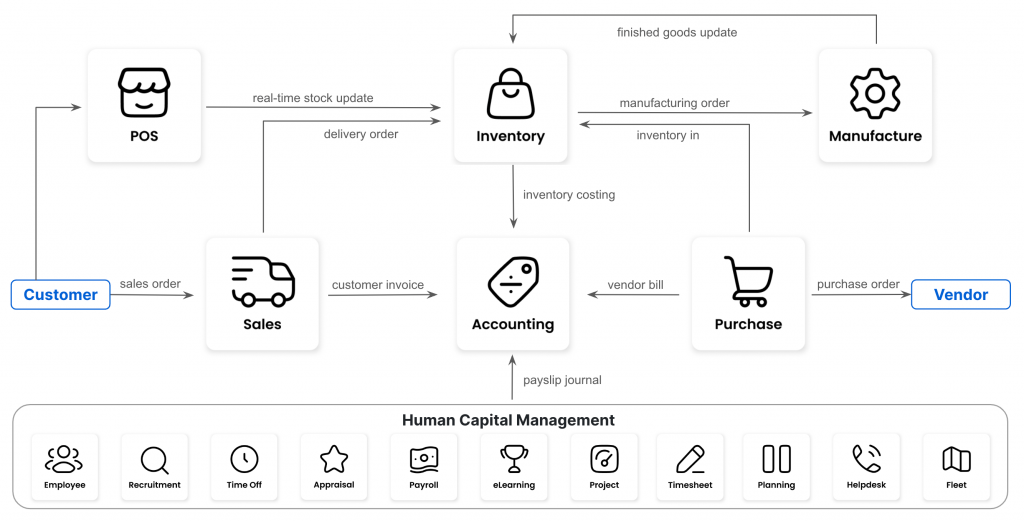

ERP works by automating the following core business processes:

Order to cash refers to all the steps involved in processing customer orders from the moment a customer places the order to when the payment is received.

Procure to pay refers to all the steps involved in procurement from the moment the procurement team places the order to when the bill is paid.

Inventory management refers to all the steps involved in inventory planning, inventory receipt, inventory transfer, and product delivery.

Production process refers to all the steps involved in the production process from demand forecasting to when production is completed. It often overlaps with inventory planning and procurement process.

License fees are paid to the company who owns the ERP, not the implementer. Usually there are server and maintenance fees to the implementer in addition to license fees.

50-75% of ERP implementation projects fail to meet their objectives.

There are many reasons for ERP implementation failures, however the top 3 are:

Most companies in Indonesia just want to replace their ineffective systems (accounting, POS, or custom-made systems) without a clear goal on what they are trying to achieve. They end up either asking for unnecessary customizations, or they just get whoever gives them the best price.

ERP systems exists to automate operations, so you have to fix (in order of priority):

We strongly suggest business owners to seriously consider transforming your businesses before buying an ERP system and do the following:

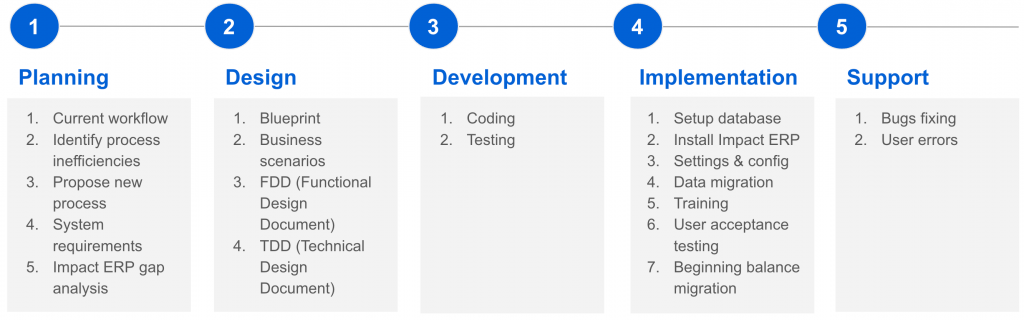

Around 26% of ERP implementations fail due to a lack of a detailed project plan. A detailed project plan is the responsibility of the ERP implementer (assuming the information needed is fully provided by the company). Therefore, choosing the right ERP vendor who has industry knowledge, understands business processes, best practices, and accounting (since every transaction will have an impact to accounting), and not just IT knowledge, is so crucial.

The goal of an ERP system is to automate and integrate the different processes and teams for efficiency purposes. For companies who implement an ERP system for the first time, it involves a huge change to the company.

It requires identifying all the different pain points of all the teams that cause inefficiencies, discussing with the team to find practical solutions to those inefficiencies, and basically changing the way they work. The change of one team will affect other teams since the processes are interrelated.

Therefore, companies need to be ready to make major changes since this requires heavy commitment (time, effort, and money). For example, companies may have to restructure their organization, removing unnecessary positions, changing employee job descriptions, changing warehouse layout, changing supplier selection process, and changing employee goals, KPI, and appraisals.

This is a digital transformation process which definitely requires top management involvement to resolve employees’ resistance to change (especially the not so open minded ones who have been around for a long time). Most companies are already comfortable with the way they work and they look for an ERP system to make their companies slightly more efficient without changing anything major.

For small businesses, the top 3 are:

Most small businesses have questionable accounting data. Therefore, even if the ERP system works to automate operations, small businesses can’t reliably analyze the data (inventory turnover, profit margins, price vs volume analysis, etc.). Sadly, most ERP implementers in Indonesia don’t have the accounting expertise to fix this problem.

Small businesses in Indonesia are generally price sensitive. It makes sense since their profit margins are generally very thin (their customers are also price sensitive). However, ERP systems are especially useful in Indonesia to automate operations, reduce operational expenses, and increase profit margins. Therefore, small business owners should care about business process optimization because they should know best what works and what doesn’t work for their employees (each company hires differently). However, most small businesses in Indonesia just leave it to the ERP implementer to decide for them. Again, most ERP implementers in Indonesia don’t have the change management expertise.

The most common ones we found are:

It takes time for employees to adjust to the new system. Make sure standard operating procedures and enough training are done so everybody knows how to adapt fast. Print how-tos and post it on their walls and near their laptops/computers/tablets.

Our recommendations are based on the following criteria:

We recommend the following 4 ERP systems:

| Impact | Odoo Enterprise | SAP Business One | Microsoft Dynamics | Netsuite OneWorld | |

| Starting price | Rp 200k/ user/month | Rp 170k/ user/month | $108 /user/month | $70 /user/month | $999/co/mo + $99/user/mo |

| Multi-company | v | v | v | v | Add-on |

| AIPS | v | v | v | v | v |

| Manuf order | v | v | v | v | Limited |

| Shop floor control | v | v | v | v | x |

| Quality control | v | v | v | x | x |

| CRM | v | v | v | v | v |

| HR core | v | v | v | v | v |

| Payroll | v | v | x | x | x |

| Mobile app | v | v | v | v | v |

Contact us to get a more detailed version of the feature comparisons with more ERP systems in Indonesia.

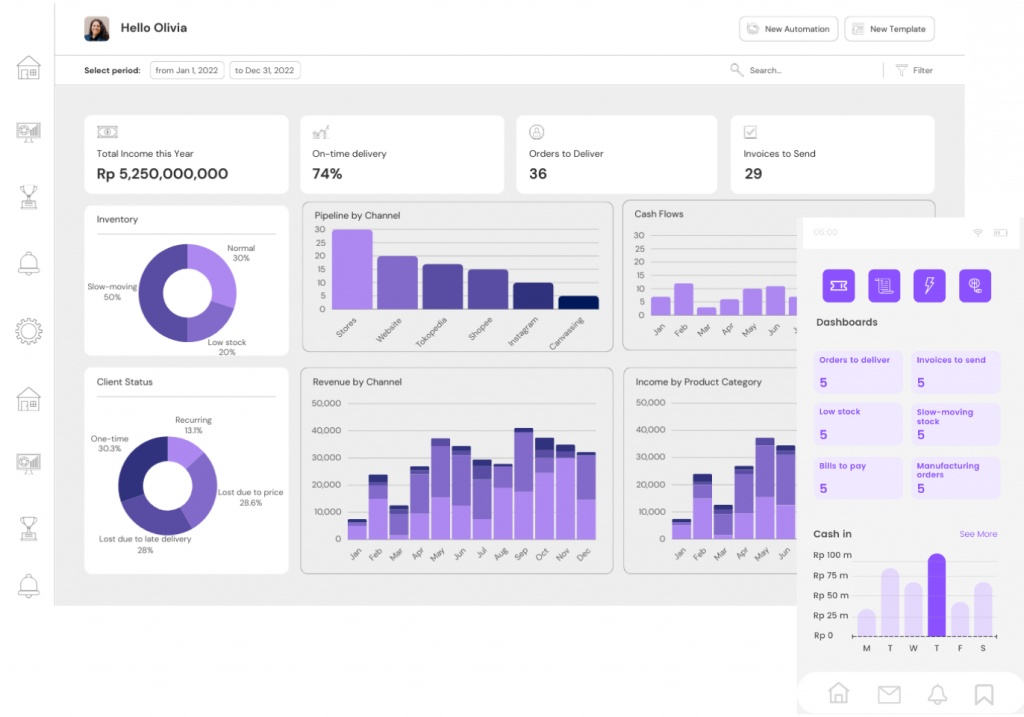

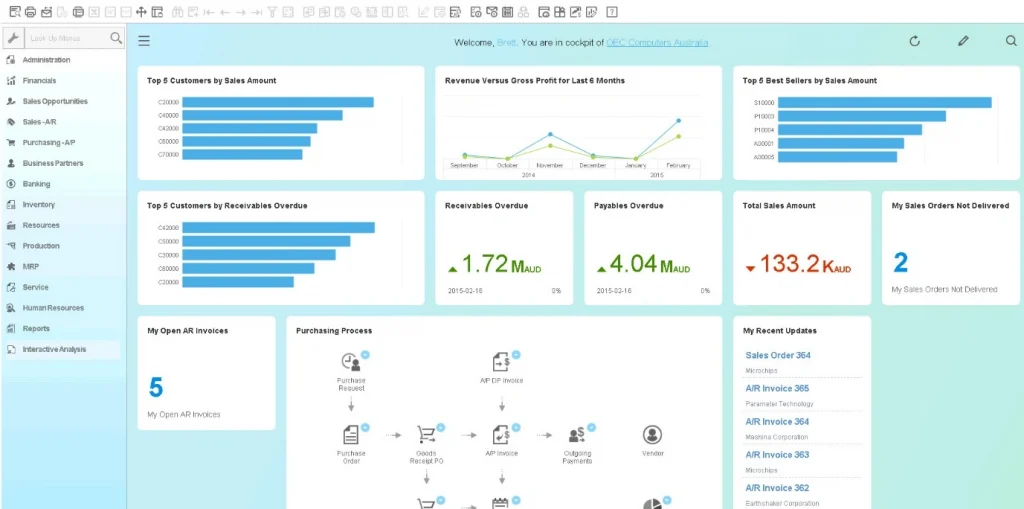

Impact is an ERP built specifically for small to medium-sized Indonesian manufacturers. It is available as cloud-based or on premise, and is ready-to-use yet customizable. Impact’s key features include:

| Team | Sales & marketing | Manufacturing | Inventory & procurement | Accounting |

| Key features | Website builder CRM Sales POS | Production planning MRP MES | Automated PO for low stock WMS Barcode & RFID Stock take Tender management | Invoicing Billing eFaktur eBupot Easy reconciliations |

| Key reports | Leads analytics Conversion analytics Sales performance reports | Batch reports Landed cost COGM Variance analysis | Stock card Expiring stocks Slow-moving stocks Stocktake Vendor performance | Financial statements Budgeting Analytics |

Starting price: Rp 200,000/user/month

In an effort to grow Indonesia’s economy, Impact has a 20% discount for small businesses. Visit them to learn more.

Pros & cons

| Pros | Cons |

| Indonesian features | Can be slow when generating reports |

| Flexible: cloud, on-premise, customizable | Limited implementation partners |

| Mobile app for business owners, warehouse team, sales team |

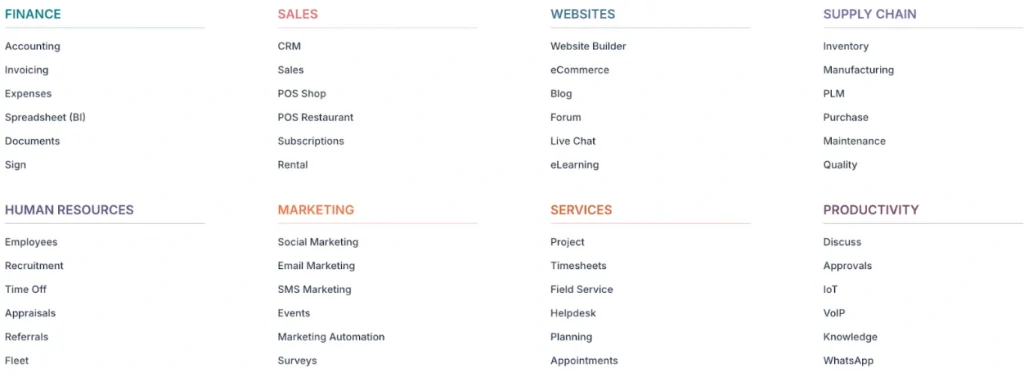

Odoo Enterprise is great for small businesses trying to implement ERP for the first time since it is affordable. It has many modules all for one price.

Although it has the open source version (Odoo Community), we do not recommend it for most companies since Odoo Community does not have an Accounting module (unless you don’t need an accounting module).

However, when choosing an Odoo implementer, make sure you choose an official partner who understands accounting, industry best practices, and Odoo limitations.

We are an official Odoo partner. Click here to learn more about our services.

Starting price: Rp 170,000/user/month

Pros & Cons

| Pros | Cons |

| Many modules all for one affordable price | Choosing a reliable partner can be tricky |

| Modular and customizable | Much customizations may be required for medium-sized manufacturers |

| Many implementation partners to choose from |

SAP Business One is SAP’s most popular ERP since it is SAP’s least expensive product. It is a reliable system rich in features, especially for mid-sized manufacturing companies. Although lacking in certain features (POS, HRIS), some implementation partners have built add-ons (at an additional price) to complete their systems.

Starting price: $108 per user per month (professional license)

Pros and cons

| Pros | Cons |

| Manufacturing features | No POS, CRM, and HRIS |

| Reliable partners | High learning curve |

| Cloud or on-premise available | Expensive |

Microsoft Dynamics 365 Business Central is a reasonably-priced ERP system best for companies within the Microsoft ecosystem.

It has the option to link the system to Microsoft Office tools, such as Outlook and Excel, to improve experiences for customers and employees.

With 49 official partners in Indonesia, implementation costs are reasonable and getting customer support should not be an issue.

Starting price: $70/user/month

Pros and cons

| Pros | Cons |

| Link to Microsoft Office tools | Requires a learning curve |

| Reasonable price | Reports may be difficult to understand |

| Simple design | Can be slow sometimes |

Netsuite is known to have a strong cloud infrastructure, allowing them to have a faster loading speed and faster real-time updates, especially on its mobile app. We also think Netsuite has the best UI design.

However, Netsuite is not available on-premise. In addition, you will be charged $999 per company per month in addition to the monthly user fee (unless you opt for the Starter Edition which will also cost you $999 per month). You will also have to be ready to pay for add-ons.

Netsuite has 8 known implementation partners in Indonesia. Although this may bring concerns regarding implementation and support, we’ve heard that Netsuite’s partner success managers are quite hands-on in helping partners with project planning and implementation, so we feel that this should not be an issue.

Starting price: $999/company/month + $99/user/month

The short answer is: when it can increase net profit and when company leaders can commit (because there may be other more urgent things that can increase net profit that leaders can focus on).

We’ve heard a lot of stories where companies try to cut costs by hiring internal software developers or freelancers because they think those are cheaper.

Majority of them ended up in failures (freelancers disappear with bugs unfixed, internal software developers are unclear of what to build while companies blame them thinking it’s their jobs, etc.) and they ended up starting all over again with professional ERP implementers. It took them years longer and a lot of money going down the drain.

This is how we recommend you to filter your ERP vendors:

Trust your instincts. It is much better to choose the more expensive ERP vendor that is more likely to bring you ERP implementation success, than to choose the cheaper option but they end up in a mess and you end up paying 2-3 times the price.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

See how our ERP provides better value.

Speak with our consultant to explore how we can improve your accounting, processes, and people.