12 Vital Retail Metrics & KPIs for Your Business Success

Our retail guide’s last chapter explored ways to boost your store’s success through innovative finance,…

Sean Thobias

November 19, 2024Warehouse managers need to be good at running things to make warehouses work better and get more done. They must find ways to make things faster, save money, keep customers happy, and ensure everyone stays safe. That’s why managers need to know all about the different jobs in the warehouse and how they affect the whole business and supply chain.

This article is a continuation of the previous chapter. It talks more about what managers do in warehouses and what problems they might face. It discusses the challenges they will face and the critical qualities they must possess.

These days, warehouse managers spend more time in front of laptops than manually patrolling warehouses. They use laptops to find the latest solutions for cost and productivity.

The job description for a distribution center manager now requires the following skills:

The warehouse manager’s primary responsibilities include:

The job description above outlines the typical expectations for a warehouse manager in today’s fast-paced business environment. This description aims for managers to provide excellent customer service while finding ways to save money by increasing productivity and performance.

Additionally, managers should effectively manage inventory and prioritize the safety and security of their staff, equipment, and stock. To fulfill these responsibilities, warehouse managers must make trade-offs and actively handle various aspects of the job.

To effectively manage a warehouse, it is crucial to adhere to the following fundamental principles:

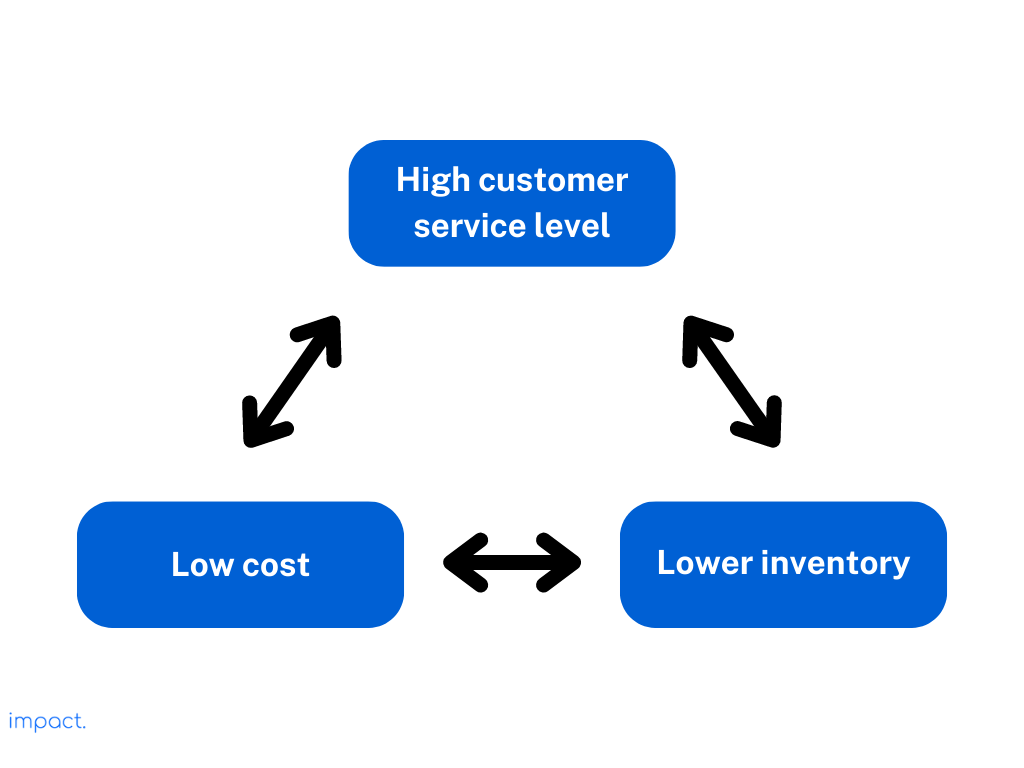

Managing trade-offs in a warehouse is very important for a warehouse manager’s job. The image below shows the leading exchanges.

Warehouse managers need to recognize and balance different trade-offs within the warehouse. Here are some examples:

Read more: 6 Warehouse Performance Metrics & Tips for Choosing Them

Warehouse managers today experience a range of pressures and challenges from different sources, both inside and outside their organizations. Here are the central challenges they face:

Companies want to spend less money on the supply chain. Transportation and warehouse managers face pressure to cut costs and make customers happier. The company must consider outsourcing specific tasks and thoroughly analyze how other companies handle logistics.

The supply chain has recently introduced new Key Performance Indicators (KPIs) called perfect order metrics. Achieving timely delivery without damage and with the correct paperwork defines an ideal order.

These metrics cover many aspects of supply chain performance. If everyone uses the same standards, they can become a leading measure for supply chains and help distinguish one company from another.

Order lead time refers to the time it takes for customers to receive their goods after placing an order. A well-run warehouse aims to minimize lead times, ensuring quality products at a lower cost. Having a shorter waiting time is a crucial factor that sets competitors apart.

Companies use different channels to deliver products and reach more customers. These channels include delivering single products to end users directly, sending specific stock-keeping units (SKUs) orders to stores, and fulfilling bulk orders to retail distribution centers.

Every shipment has different rules for collecting it and what equipment to use. It also takes time to process orders and use other shipping methods.

The just-in-time method and more online sales and initiatives like efficient consumer response (ECR) and quick response (QR) have made smaller but more frequent orders necessary. As a result, warehouse operations need to change from picking full pallets to picking cartons and individual items.

Companies should adjust their strategies to deal with uncertain sales. This adjustment means adding more resources during busy times and reducing operations during slower periods.

Having a wide variety of products is excellent for consumers, but it creates a problem for warehouse managers. They struggle to find the right storage spots that are both affordable and practical. If the picking locations are too high, it becomes difficult for workers to reach the products, which lowers productivity.

Retailers want to stand out by offering different product options. As a result, the company decided to change how they handle inventory in the warehouse. Instead of storing all products immediately, they only hold the basic stock and add more when they receive an order.

Warehouse managers need to find ways to attract new staff. Currently, they have hired workers from other countries to fill the gaps. One approach is to hire supervisors who can speak more than one language.

Another way companies can improve is by offering flexible working hours and shifts. According to Parkinson’s law, work takes up the available time. Lack of time can be a problem in warehouses with little stock. Companies can better match their resources to the demand by using annual hours.

Warehouses create much waste daily. Examples of these wastes are stretch-wrap, cardboard, tape, and pallets. So, warehouse managers must control this waste by saving costs, recycling, reusing, and converting energy. Energy use also affects warehouse products, such as lighting, equipment, and heating.

Supply chains create many data because their main job is to transfer information. Warehouse managers can use this data to analyze and track things. Being able to track goods in the supply chain is very important, especially for food and medicine.

The warehouse supervisor plays a crucial role in warehouse operations. They oversee many staff members, which depends on factors such as the nature of work, warehouse size, and the abilities of their supervisors and staff.

According to a recent survey conducted by Cranfield University (Baker and Perotti, 2008), the average ratio of operators to supervisors is as follows:

In the warehouses we have today, supervisors need to know how things work and be good at managing. According to Ackerman (2000), a good supervisor can encourage people to share their ideas and discuss them with their staff and colleagues. So, supervisors should have these essential qualities:

It’s essential to understand and communicate messages clearly and directly. When there’s miscommunication, it can cause confusion, waste efforts, and generate missed opportunities.

Managers and supervisors should not closely watch over tasks after delegating them, but they should still take responsibility. They need to keep an eye on task progress and give feedback to employees about their performance.

Supervisors and managers should understand their employees and adapt how they motivate and give feedback to meet each person’s needs. It’s crucial to provide consistent feedback to staff, even when they are doing well, just like when they are not meeting expectations.

Problem-solving and decision-making skills go hand in hand. To effectively utilize these skills, you must identify and develop options and take decisive action. As you walk around the warehouse, actively search for staff members waiting for something to happen before they can proceed with their tasks. Determine the cause of the bottleneck and make necessary changes to the process.

In today’s fast-paced warehouse environment, supervisors must be flexible and respond promptly to changes and urgent requests. Additionally, they need to supervise and carry out various tasks actively.

Warehouse supervisors must understand company policies and procedures to train operators effectively and coordinate their work. Supervisors need to be involved in preparing warehouse procedures and processes, as they need to know the administrative and operational steps involved.

Supervisors must share their knowledge with staff to keep things consistent and sustainable. When staff members receive proper training, they have a better chance of becoming supervisors in the future.

Supervisors must actively understand customer preferences and operation management to ensure customer happiness. At the same time, supervisors need to think about the costs and possible trade-offs.

Supervisors should assign company goals to their teams and clearly explain how the team will contribute to these goals.

Read more: Warehouse Cost: 2 Determination Systems & Reduction Tips

Warehouses need an experienced and knowledgeable manager who can train and motivate supervisors and operators to make it run well. However, finding the right employees is challenging due to an aging population.

Managers have to make choices when dealing with these challenges. They have to balance reducing costs and improving customer service. Comprehensive and ongoing training enables managers and supervisors to acquire the necessary skills.

In the next chapter, we’ll talk in detail about the picking process in the warehouse and its related procedures.

Ackerman, K. B. 2000. Warehousing Profitably. Ohio: Ackerman Publications.

Baker P, Perotti S. 2008. UK warehouse benchmarking report. Cranfield School of Management.

Richard G. 2011. Warehouse Management. Great Britain: Kogan Page Limited.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

75% of digital transformation projects fail. Take the right first step by choosing a reliable long-term partner.