Inventory Turnover: Formula and 5 Ways for Better Results

Overview The inventory turnover ratio is a crucial metric in retail, helping businesses gauge their…

Sean Thobias

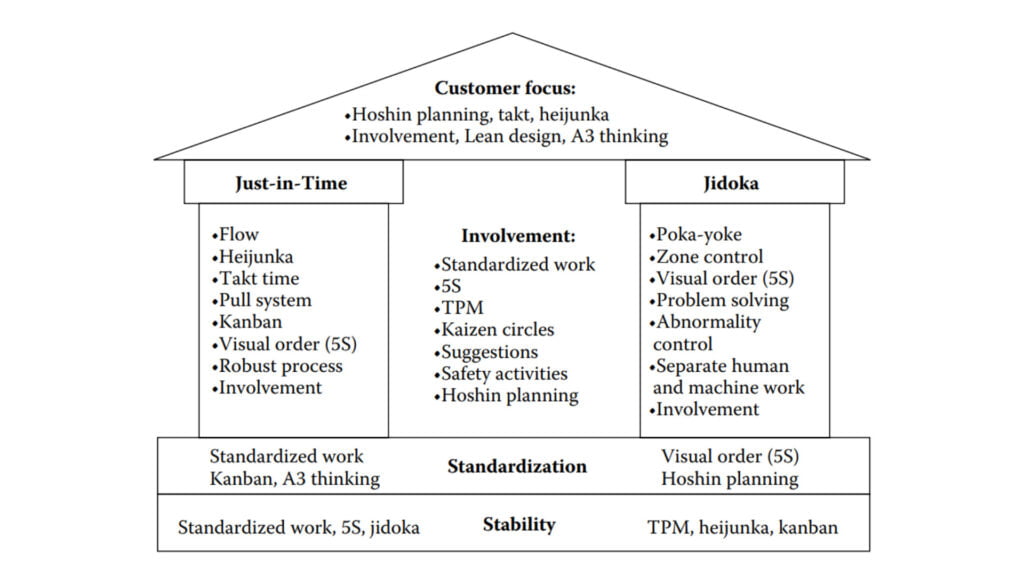

January 23, 2024The House of Lean Production relies heavily on stability as its core foundation. Without it, achieving higher performance at Toyota is not possible.

The first step to ensure stability is to implement visual management. Several other elements reinforce it, including standardized work, 5S, Jidoka, Total Productive Maintenance (TPM), heijunka, and kanban. These various components collaborate to foster stability throughout the production process.

Source: Dennis, P. (2017); Lean Production Simplified; Basic Image of Lean Production

This article focuses on 5S and visual management in lean manufacturing, which helps create stability. Let’s dive in and learn more about them.

The production base is the standard expectation. It’s what should occur in the production process. However, Toyota sets itself apart with its distinct approach. They define standards as precise descriptions of the desired conditions.

Standards at Toyota hold great significance. They bring problems to light and motivate the company to address them promptly. Furthermore, Toyota communicates the ideal standard in a straightforward, clear, and visually apparent manner.

Toyota follows a lean manufacturing improvement process, which includes:

In a lean manufacturing system, standards directly link to actions. Let’s explore the three types and their strengths:

Read more: Lean Manufacturing: Definition & its 3 Benefits

Visual management is a strategy that aims to handle exceptions and achieve excellence. It involves creating a workplace where non-standard conditions can promptly be spotted and fixed.

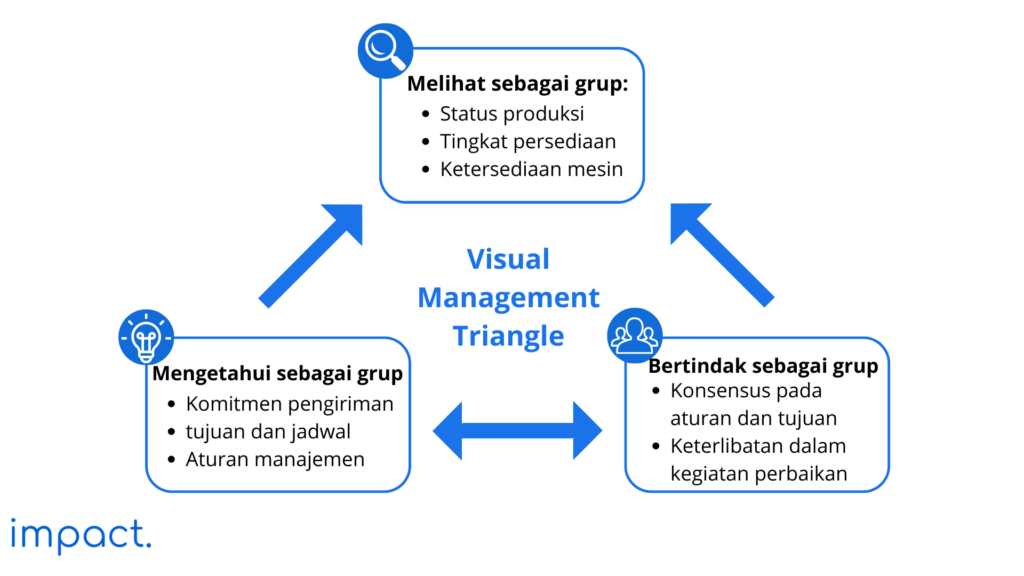

According to Michel Greif’s book, “The Visual Factory,” the visual management triangle is defined as follows:

The picture reveals that individuals within a group perceive actions, knowledge, and perspectives in varying ways. With their bright displays and visual representations of production and inventory, computers will become more important on the production floor.

There are four levels of visual management in application:

Many organizations limit visual management to Level 1, which involves signs that convey instructions or restrictions.

Level 2 holds more power as it can effectively capture people’s attention and awaken them to something new. A traffic light serves as an excellent example of Level 2 visual management. It signals, “The light is turning green. You may proceed with your journey.”

Having the right tools in the correct position is crucial in manufacturing. It ensures two key things: (a) availability when needed and (b) awareness when they’re not.

In manufacturing, we use poka-yokes to minimize defects in the product. We implement alarms on torque wrenches, electronic lights, and safety devices that disable engines if a team member enters the line of fire. This way, we receive timely notifications when errors occur.

The 5S system is straightforward, comprising five key components: sort (seiri), set in order (seiton), shine (seiso), standardize (seiketsu), and sustain (shitsuke). Its purpose is to facilitate visual management, creating a work environment that is self-explanatory, self-regulating, and continuously improving.

Toyota values a clean and organized workplace as the bedrock of improvement. Let’s delve into each component of the 5S system, which defines the ideal conditions at Toyota.

Sorting involves eliminating unnecessary items from the workspace to enhance production efficiency. Accumulated piles of unneeded items impede smooth workflow, increasing complexity and longer waiting times.

To sort effectively, categorize items into four distinct groups:

There are two methods you can use to simplify the elimination of unnecessary items. They are just in case management and red tagging. We will further explain them below.

Just in case management

This mindset is harmful because it ends up increasing production costs. Unnecessary items take up valuable space on shelves and floors. Even though they might have been helpful in the past, they are now outdated and never thrown away. These items make it hard for workers to find what they need.

As a result, companies need more space, racks, pallets, forklifts, and more extensive warehouses. They also need to hire more people to handle operations and management.

Red tagging

Identify your essential requirements and eliminate everything else to meet your production goals. The required method for organizing is through red tagging. Red tag labels provide crucial information about an item’s classification, ID, quantity, reason for red tagging, work component, and date.

Items not needed during sorting need to be red-tagged. Here’s the key to implementing red tagging:

Set in order is the crucial step of arranging everything in a convenient and accessible manner. The process begins only after completing the sorting phase. The main aim is to create a simple and consistent way of organizing tools, making finding and using them easier without unnecessary movement.

To streamline set-in orders, workers should initiate the process based on the tool and material usage frequency in production. Consider the following factors:

To simplify the set-in-order process, you can apply the following methods:

Rationalize location

Select a pilot area and create two maps on large sheets of paper. Depict the area’s description and potential outcomes. Outline the boundaries of the chosen location and use small sticky notes to represent the items within it (maintaining scale).

Attach the sticky notes to the map to reflect the current situation. Utilize red strings or arrows to illustrate the current movement of the matter.

Place a sizable chart beside the map and encourage team members to jot down their concerns, potential countermeasures, and comments. Allow the chart to remain for at least one week to gather feedback.

Then, create a what-could-be map using the same approach. Focus on addressing the identified hassles mentioned by the team members. Acknowledge and respond to each suggestion on the posted chart, minimizing unnecessary steps.

Finally, pick a vacant area in the plant or a parking lot. Grab some masking tape or chalk and draw out your desired layout. Use cardboard to mimic large equipment and colored chalk to indicate material movement. Once you’ve double-checked your design, it’s time to start moving the equipment.

Organize & apply color

For improved organization, align the remaining items following the three dimensions and incorporate color into the workspace. Keep in mind the fundamental principles of organizing: Where? What? How many?

Enhance workflow by rearranging equipment and parts racks. Implement a visual system, such as colored tape, to indicate the number of units, clearly displaying maximum and minimum levels or the required space. Establish consistent color standards and actively apply them in your workplace.

Ensure that everything is easily located and readily accessible. It should be effortless for anyone to find any item at any given time, and non-standard situations should be immediately apparent to everyone.

The company must effectively remove all dirt and maintain workplace cleanliness daily. Our 5S team needs to determine the following: what needs cleaning, how to clean it, who will perform the cleaning, and the level of cleanliness required.

In the 5S system, everyone is responsible for cleanliness. While the cleaning staff can still handle more extensive tasks, employees themselves should take care of the cleaning details. To cultivate this mindset, we must provide staff training and foster a corporate culture emphasizing responsibility.

Cleaning targets encompass storage areas, equipment, machineries, and their surroundings, such as hallways, windows, meeting rooms, offices, and regions under stairs. Create a comprehensive checklist detailing the specific items that require cleaning.

Determine the cleaning methods and ensure suitable equipment is available in a central area. Pack the following supplies at a minimum: broom, dustpan, hand brush, mop and bucket, duster bag, and a large trash can.

Post clear cleaning responsibilities and schedules. Incorporate a “5-minute cleanup” into every job to foster ownership and mutual respect among team members.

In addition, S3 entails equipment inspection, requiring production team members to assess their machinery’s condition regularly. They should receive training to identify minor changes in sound, smell, vibration, temperature, or any other indicators.

Develop inspection check sheets specifically for machines to facilitate these tasks. Lastly, train team members to address underlying causes of hygiene issues.

Standardization is essential for ensuring the consistent and daily implementation of the 5S concept. Clear, simple, and visual standards are critical in this process. Implementing practical solutions to recognize and resolve any uncommon situations is essential.

To establish regular habits, companies can utilize schedules and checklists. The production board, where the kanban is displayed, serves as a standard, providing information on what to create, how many to make, and the deadline.

Standardization involves three steps to ensure consistent and correct implementation of the 5S pillars:

Employees need a clear understanding of their expectations to perform their duties effectively. Therefore, explaining the steps for concisely implementing 5S is crucial. To facilitate their knowledge, we should write their responsibilities on a checklist they can easily access throughout the day.

Properly training employees is crucial to ensure the success of the 5S process. Employees who understand the process are more likely to execute it effectively.

Once you’ve taken these steps, regularly assess performance. You can form a team with employees from different departments or have department supervisors conduct evaluations. Ensure a system is in place to ensure tasks are consistently completed.

To have a successful S1 to S3 process, you must meet the following standards:

Standards for S1 to S3

The S1 standard (sort) must include the following:

The S2 standard (set in order) should include the following information:

The S3 standard (shine and inspect) should include the following:

Adopting a standardized method for assessing S5 status is essential to ensure consistency. We typically customize the 5S scorecard to align with our workplace and regular inspection schedule. Ultimately, integrating 5S into our standard work procedures is crucial.

Engagement holds the key to ensuring the sustainability of 5S as our habitual way of conducting business. Keeping our employees motivated and aligned on the right track is crucial.

To support the long-term implementation of 5S, we can adopt several approaches, such as:

Promotion & communication

Here are some ideas to promote 5S effectively:

Training

Incorporate 5S into the lean manufacturing training plan. Determine the appropriate level of training for each individual and promptly provide it. Here’s a simplified training plan:

Investing in 5S training results in quick returns. It introduces team members to the language of lean manufacturing and serves as the foundation for all future activities.

Before implementing the 5S concept in the company, it’s essential to take specific preparatory steps. These include:

Defining these concrete factors will kickstart the 5S implementation process.

Moreover, active employee involvement plays a crucial role in the success of 5S. Employees should actively demonstrate openness, willingness, and commitment to contribute to the success of 5S projects. Their active support is vital for achieving positive outcomes.

To boost employee engagement, try the following methods:

Visual management and 5S are essential foundations of lean production. Visual management has four implementation levels, from the lowest to the highest.

5S is a system that supports visual management and consists of five components: sort, set in order, shine, standardize, and sustain. Each of them has a method to make implementation easier.

To successfully implement 5S and visual management, companies should involve team members in inspecting and improving equipment. The following chapter will discuss another essential foundation of lean production called Total Productive Management (TPM).

Dennis, P. (2017). Lean production simplified: a plain-language guide to the world’s most powerful production system. Crc press.

Impact Insight Team

Impact Insights Team is a group of professionals comprising individuals with expertise and experience in various aspects of business. Together, we are committed to providing in-depth insights and valuable understanding on a variety of business-related topics & industry trends to help companies achieve their goals.

75% of digital transformation projects fail. Take the right first step by choosing a reliable long-term partner.